Location: Home >> Detail

TOTAL VIEWS

J Sustain Res. 2023;5(4):e230016. https://doi.org/10.20900/jsr20230016

1 Geological and Mining Institute of Spain (IGME), Spanish National Research Council (CSIC), C/ Ríos Rosas 23, Madrid 28003, Spain

2 Instituto de Carboquímica (ICB-CSIC), Miguel Luesma Castán 4, Zaragoza 50018, Spain

3 Departamento Técnicas y Proyectos en Ingeniería y Arquitectura, Universidad de La Laguna (ULL), La Laguna, Tenerife 38200, Spain

4 Departamento de Ingeniería Agraria y del Medio Natural, Universidad de La Laguna (ULL), La Laguna, Tenerife 38200, Spain

* Correspondence: Juan C. Santamarta.

This article belongs to the Virtual Special Issue "Sustainability in the Built Environment"

The design of a geothermal heat pump system and geothermal heat exchangers to replace conventional cold and heat production systems in a winery on the island of Lanzarote (Canary Islands, Spain), taking into account its active volcanic geological peculiarities, is presented in this work. Firstly, a study was carried out to estimate the cold and heat needs of the winery during its operation. A calculation program was implemented in Matlab software framework to estimate the influences of the winemaker’s decisions on the cold and heat consumption of the winery. Once the needs were determined, a commercial geothermal heat pump (GHP) was selected, using exhaust heat to produce hot and cold water at the same time. After assessing hot and cold-water consumption along with heat pump requirements, a field of closed-loop borehole heat exchangers (BHE) was designed using a finite element heat transport numerical model. The existing geological profile, characterized by alternating basalt lava flows and pyroclasts, was carefully considered. The high porosity of the pyroclastic layers resulted in a 20.1% reduction in BHE performance compared to the initial expectations. Consequently, the depth of the 12 BHE was increased 21.9 additional meters from the original design. Thus, it was concluded that the alternation of basaltic lava flows and pyroclasts is prevalent in volcanic islands, emphasizing the need to attentively account for these pyroclastic layers in such environments.

The energy accumulated in Earth represents an opportunity to address, at least in part, the problems related to energy supply, energy efficiency and respect for the environment. Conventional energy resources, such as oil, natural gas, coal and uranium, result originate from finite energy resources extracted from the Earth’s crust. Only one energy resource obtained from the crust is renewable, namely geothermal energy [1]. This energy comes in many different forms, depending on the specific conditions of the resource. In volcanic areas or subduction of tectonic plates, deposits of water/steam of very high energy and temperatures (150–350 ºC) are sometimes produced, and are known as high enthalpy resources. These can be used for electricity production in binary cycles due to their high quality. By contrast, in sedimentary basins, low enthalpy deposits are can be found, with temperatures typically ranging between 50 and 90 ºC. These are often used for direct thermal uses, such as thermal baths and swimming pools, heating, fish farms, greenhouses, etc.

However, it is often the case that geothermal energy resources are not found at the site where facilities are located. Nevertheless, it is possible to obtain it from the ground with technologies that take advantage of very low enthalpy resources, and this energy is available throughout the globe. The quality of the geothermal resource varies from site to site and depends on the following parameters: geofluid temperature, geothermal well depth, chemical composition of the rock formations in the well and amount of the available geofluid [1,2].

The ground possesses a high heat storage capacity and low thermal conductivity. In fact, the temperature remains practically constant throughout the year at 15–20 m deep [3]. These conditions can provide renewable energy to supply the heating and cooling needs of a building during a year, and even generate a certain amount of hot water. Undoubtedly, the equipment most used for this purpose are geothermal heat pumps (GHPs), which are capable of extracting heat from the ground and injecting it into a building, or, working in reverse cycle, extracting it from the building and injecting it into the ground. In cooling mode, heat is extracted from the building and transferred to the ground. In heating mode, heat is extracted from the Earth and transferred to the building [4,5].

The exploration and exploitation of geothermal energy has increased globally in the recent decades in the pursuit of sustainable [6], low carbon emission energy resources [7]. Although geothermal energy is one of the newest types of renewable energy, it certainly shows high potential [8–11].

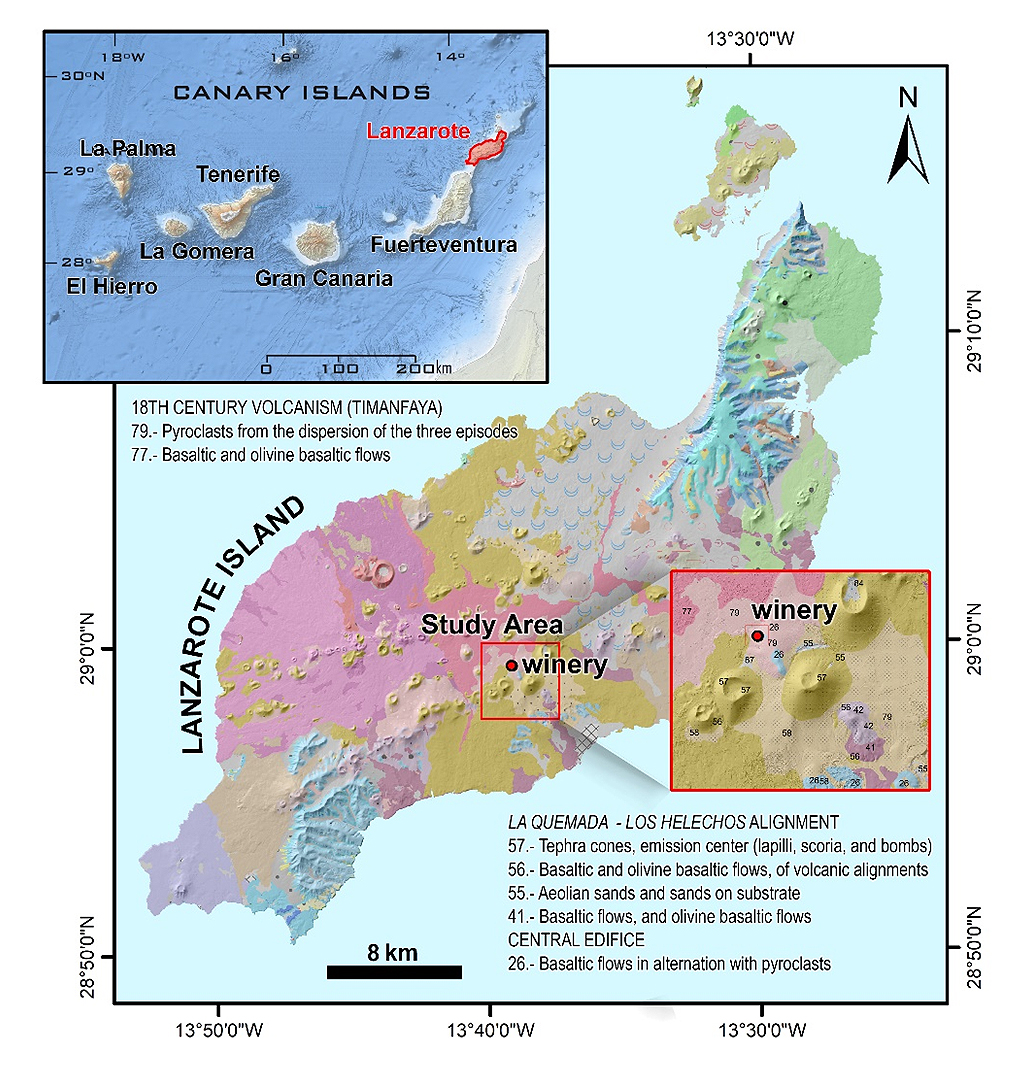

Winemaking is a seasonal process, in which production is concentrated in a short period of time and may vary depending on the climatic conditions of each year. Despite being associated with various environmental problems, the wine industry has traditionally been subject to a less strict regulatory attention compared to other industries [12]. On average, the winery under study, which is located on the island of Lanzarote (Canary Islands, Figure 1), produces 240,000 kg of white grapes per year from a harvest that usually takes place in August.

Figure 1. Geological map of the study area on Lanzarote Island, Canary Islands (Spain). Extended geological data and detailed legend can be found in http://www.igme.es/. Projection: WGS 1984 Complex UTM Zone 28 N, Datum DWGS1984.

Figure 1. Geological map of the study area on Lanzarote Island, Canary Islands (Spain). Extended geological data and detailed legend can be found in http://www.igme.es/. Projection: WGS 1984 Complex UTM Zone 28 N, Datum DWGS1984.

Regarding the energy consumed by the winery industry, much of it is used for refrigeration purposes, due to the importance of operating at temperatures below the climatic ones, in order to ensure product quality [13], as wine temperature greatly influences the oenological processes. An increase in temperature accelerates the dissolution of solids, the volatilization of gases and liquids and the speed of the chemical reactions. On the other hand, temperature decreases the solubility of gases and exerts a complex action on the development of microorganisms (at first, favourable action and then, an inhibitory one) and on the products of their metabolism [14]. That is why the distribution of energy consumption is not homogeneous, since the consumption of energy for refrigeration purposes occurs especially during white wine vinification and different auxiliary operations. In general, refrigeration needs vary throughout the day, as many of the processes take place intermittently at different times of the day. In addition, energy consumption depends on the time of year, with a peak occurring towards the middle of the harvest period, when the arrival of the grapes overlaps with the fermentation process [15].

This paper aims to comprehensively investigate the cost-effectiveness and thermal adaptability of low-temperature geothermal facilities applied to buildings. Our analysis demonstrates the viability of low enthalpy projects, emphasizing their reduced dependence on primary energy and the associated environmental benefits, including a notable reduction in CO2 emissions. Geothermal energy emerges as a clean, efficient, and sustainable alternative to conventional heating and residential air conditioning systems. Additionally, this work addresses the geological challenges unique to active volcanic islands, particularly the presence of highly porous pyroclastic layers, shedding light on their impact on drilling depths and associated costs. Despite these challenges, shallow geothermal energy remains the most efficient electrification technology for the thermal sector. This study provides valuable insights to reduce uncertainties and prevent suboptimal practices in the implementation of geothermal systems in active volcanic island environments, ultimately advancing the development of efficient and sustainable energy solutions in these complex settings.

Cooling and Heating NeedsRefrigeration and heating needs vary throughout the wine-making process, peaking around the harvest stage, when the processes with the highest thermal demands are carried out. As previously mentioned, the production of quality wines requires great flexibility to the facility, due primarily to the characteristics of the harvest (in terms of quantity and quality) as well as the technical decisions adopted by the winemaker, which can vary depending on new production methods, raw material conditions and market needs.

For this reason, computer tools were used to calculate the needs in different scenarios, as well as to verify that the facility size was in accordance with these assumptions. The processes studied and measured were: refrigeration needs for desludging; desludging thermal losses; refrigeration needs for fermentation; fermentation thermal losses; and losses associated to the distribution of the cooling fluid.

In addition, other cooling and heating processes, showing a smaller impact on the demands of the GHPs facilities were assessed: maintenance of ideal temperature of the elaborated wines; generation of domestic hot water for various uses; production of hot water for tank cleaning; and production of hot water for disinfection of the bottling line.

Energy saving measures allowed these processes to be optimised, thus achieving a significant reduction in the electric energy demand of the processes, by implementing GHPs with higher energy performances [16].

The winery’s refrigeration equipment is designed to meet the needs of refrigeration during the harvest season. In the specific case of a white wine vinification plant with controlled fermentation, the following aspects must be known [17]: (1) The harvest calendar as well as grape entry into the winery. Potential date variations should also be known and taken into account. The energy demand needs to be calculated with different examples of entry calendars. Refrigeration energy consumption showed a specific maximum value regardless of the annual quantity of grape processed. (2) Quantity of the grape must to be extracted and fermented at a controlled temperature. The winery is located within a region with a controlled denomination of origin and its objective is to obtain high quality wines, so that all the grape must has to be fermented at a controlled temperature. (3) The average climatology during the period of harvest and fermentation of the grape musts, with an emphasis on the maximum monthly average temperatures. The effect of climatology is only relevant when using a GHP with heat sink in contact with ambient air. With regard to the study winery, its GHP heat sink is located in the ground, thus maintaining fairly constant conditions throughout the year, so that the effect of the external temperature is minimal. (4) The ideal fermentation conditions, temperature and thermal jump between these conditions and the refrigerant used. In this case, normal temperatures of 16 ºC to 18 ºC have been applied. (5) Fermentation kinetics, and evolution of heat production during fermentation. Fermentation kinetics were simulated using the empirical estimation model proposed by López and Secanell [18]. (6) The most appropriate size for the fermentation tanks and filling level. In this case, commercially available cylindrical steel tanks with a cooling jacket, and a capacity of 125 hectoliter were chosen.

Calculation FunctionAll the starting conditions to perform the calculations were entered in a Matlab function called PFC_demandas_frio.m. This function performs the calculation for the energy demand autonomously and has the following elements:

Start dataThe baseline data were organised into subsections containing all the parameters to be considered:

Winery logistics data: Daily entry of grapes; pressing yield: ratio between the grape must leaving the press and the grape being processed; racking yield, i.e., the ratio between the clean grape must obtained after the racking and the grape must obtained from the pressing; production yield, i.e., the value established by the CRDO (Regulatory Council for Denomination of Origins) as litres of wine obtained per kg of grapes from the region; phase difference, i.e., the hours passed between pressing, racking and fermentation; harvesting days, i.e., the number of consecutive days of grape entry; grape entry temperature; racking temperature; cooling fluid temperature; controlled fermentation temperature; duration of fermentation; and duration of draining.

Grape must data: Total grape must acidity, measured as tartaric acid content; initial sugar content in grape must; grape must density; and grape must specific heat.

Environmental data: Ambient temperature and dew point temperature inside the winery.

Tank data for fermentation and racking: Tank diameter; tank height; tank cooling jacket height and tank volume.

Refrigerant distribution pipe data: Total length of the distribution Line; outside Diameter of the pipe; pipe thickness; thermal conductivity of pipe insulation; thermal insulation thickness; estimated power of the facility; temperature increase applied to the cooling water; water density under conditions of use; and number of maximum GHP starts allowed per hour.

Change of units: Conversion coefficient between kcal and kJ.

With all these data entered, the kilograms of grapes being processed per season can be calculated, and an estimation of litres of wine produced can also be derived from it. The kilograms of processed grapes were calculated by multiplying the daily entry of grapes by the number of harvest days. The quantity of wine produced was determined by multiplying the kilograms of processed grapes by the production yield.

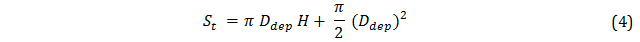

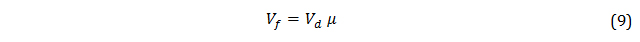

RackingThe cooling necessary to carry out this process is (see the definitions of the abbreviations in the equation in Table 1):

The decrease in temperature is considered to be is achieved in less than one day and that no more than one batch per day will be processed.

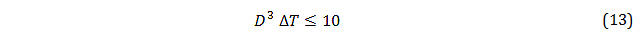

Losses per wall during desludgingDesludging is carried out in uncoated steel tanks, so that the heat flows from the outside to the grape must, which needs to be kept at a low temperature. First, the convection heat transmission coefficients were calculated according to the recommendations of the IDAE insulation design and calculation protocols (IDAE, 2007) [19]. The deposit was assimilated to a wall in turbulent regime, thus following this equation:

In this case, the following equation applies:

With ∆T being the difference between air temperature and surface temperature. Then, h1 is obtained as the coefficient between the tank wall and the air, and h2 as the coefficient between the jacket and the air.

Next, we considered the surfaces in contact with the environment of the winery. Two surfaces were differentiated; on the one hand, the cooling jacket, at temperature Tr, and the rest of the tank walls, with a temperature Td. Using the formula of the cylinder, the total surface area of the tank can be obtained:

The surface jacket is:

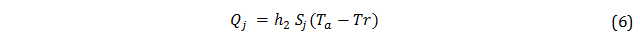

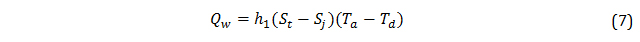

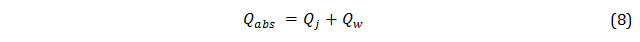

The heat transmitted through the jacket is:

The heat transmitted through the rest of the tank walls is:

And, thus, the total heat absorbed during the 24 hours desludging will be:

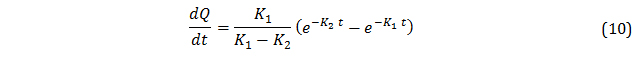

Fermentation was calculated using the model presented by López and Secanell [20] on heat generation during fermentation. This model represents the generation of heat from a fermenting grape must tank, which is dependent on the acidity and sugar content of the grape must and the controlled fermentation temperature. The total volume to be fermented equals the input volume to be racked by the desludging yield:

Once all the data needed to perform the function PFC_fermentacion.m was obtained, the first step is to investigate the heat generation data from a single deposit as a function of time. The function PFC_1cuba.m was used to do that. This function performs the following model:

From this formula, a value of dQ/dt was obtained for each hour ranging from 0 to 240, and assuming that fermentation lasts 10 days. The usual method in the winery consists of working in batches, with tanks at different stages of fermentation, and different amounts of heat generated at each stage of the harvest. To quantify the effect of these tanks, all batches were assumed to be equal in quantity, acidity, sugar content, same fermentation temperature and periodically produced (usually, one batch per day). Taking these considerations into account and using the PFC_sumatorio.m function, the total heat generated at each moment by the fermenting tanks was obtained. To accomplish this process, matrices were used with Matlab program. The matrix has as many columns (m) as the fermentation hours needed for the entire winery, and as many rows (n) as batches undergoing fermentation.

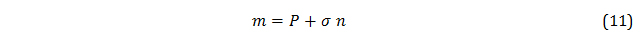

The total number of processing hours was calculated according to the following equation:

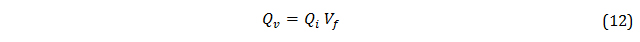

The PFC_sumatorio.m function places a batch of fermentation in each row of the matrix, matching the column number with the time at which that amount of heat was generated. Finally, the sum of each column is calculated, and a vector is obtained containing the values of total heat generated by fermentation per hour since the beginning of the process. Vector Qv was calculated as follows:

The next step consists of converting these hourly power values into values of energy needed per day, as the fermentation process does not show great variations throughout the day, and the cooling system has a refrigerant buffer tank which is able to absorb fluctuations in demand throughout the day.

The system is therefore calculated to meet the daily cooling requirements. The change of magnitude from kcal/hour to kJ/day was performed to allow the operation with the other loads of the system in the same units. To achieve this purpose, the PFC_valor_diario.m function was used to obtain the fermentation heat production for each day. This function separates the Qv vector into groups of 24, which represent a day, and performs the defined integral of the energy for 24 hours, thus allowing to obtain the value of the heat energy produced by the fermentation process each day.

Wall losses during fermentationFermentation, like desludging, takes place in uncoated steel tanks. Therefore, this calculation was made using a Matlab equation called PFC_losses_pared_deposito.m, and repeating the same process described for desludging.

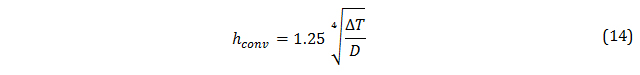

Losses in the cold-water distribution lineFinally, the cold losses occurring in the refrigerant distribution lines inside the winery were considered. Firstly, the coefficient of heat transmission by convection between the pipe wall and the air in the winery facility was calculated. For this purpose, the method recommended by IDAE was used. In this case, it is a horizontal pipe in laminar regime:

Thus, the following equation applies:

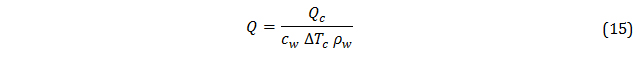

Next, it must be verified that the selected pipe was correct for these conditions. To do this, the water circulation speed was checked to ensure it was withing the 0.5 to 3.5 m·s−1 range. First, the required flow rate was calculated according to the following equation:

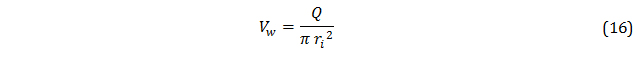

The velocity of cold-water circulation was calculated as follows:

Once the internal diameter of the installation pipe was verified to be adequate according to the circulation velocity of the cooling water, the pipe insulation was also assessed. To start with, the insulation thermal resistance was calculated according to the following equation:

And the thermal resistance of the air was:

It has to be verified that this temperature is higher than the spray temperature in the given conditions. For example, for indoor conditions of 18 ºC and 90% relative humidity, the spray temperature would be 16 ºC. Once it was verified that the thermal insulation met the requirements, the power loss of the entire line was calculated.

UnificationAs a last stage, the loads for each one of the previous sections had to be added together. To do this, the function named PFC_unifica.m was used, which sorts out each of the cooling loads in a matrix and obtains the total value for each day. With this value, Qt vector is obtained, thus providing the daily cooling energy required. The maximum daily Qt value is used to determine the dimensions of the GHP. The sum of all the monthly values of harvest is also be used to calculate the dimensions of the installation’s geothermal probes.

Heating RequirementsThe winery facility also needs hot water for bottling line disinfection, tank cleaning and domestic hot water (DHW) for the workers’ use. Considering a demand of 15 L per person and day, and knowing that at peak production the winery has 15 workers, the demand for domestic hot water would be 225 L·day−1. Therefore, the minimum volume of hot water accumulation was established as the sum of the needs for bottling disinfection and DHW, i.e., 725 L. The second largest commercial storage tank was selected, i.e., the 1000 L DHW storage tank. The energy to heat that amount of water was calculated according to Equation 1, and was estimated to be 188,550 kJ, i.e., a heating power of 2.2 kW.

Furthermore, the bottling machine must be rinsed before use. Each wash consumes a total of 500 L of water at 90 ºC for the disinfection of all the pipes, and the process takes place twice a month. The facility was designed in such a way that the bottling tank is filled with hot water produced by the GHP at a temperature of 60 ºC. The rest of the energy needed to reach 90 ºC is obtained via an electric resistance incorporated into the accumulator. The tanks can be washed with cold or hot water. However, the advantage of hot water is its greater descaling power, thus achieving savings in the use of cleaning products. Therefore, whenever available, hot water is used to wash the tanks.

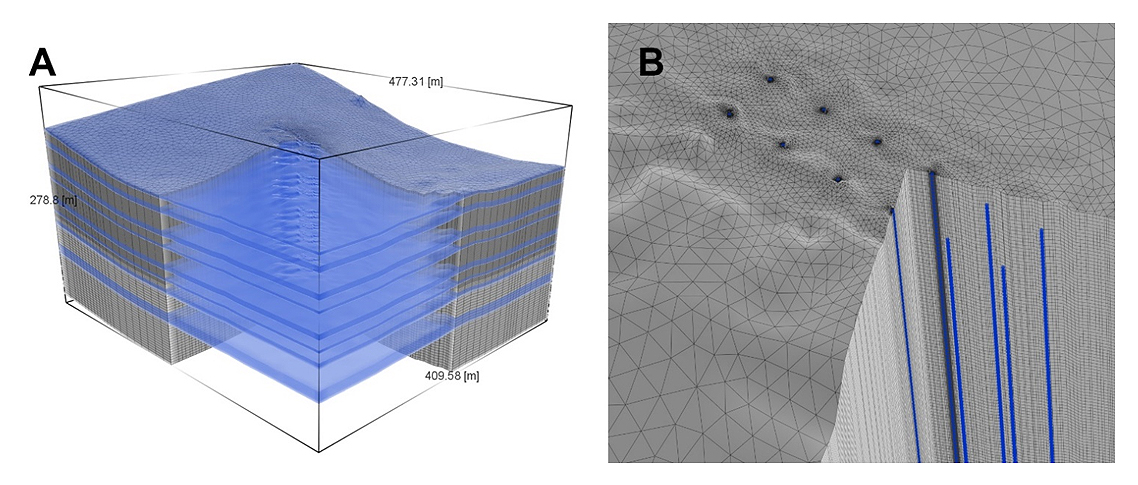

Closed-Loop Borehole Heat Exchangers Field DesignThe closed-loop vertical Borehole Heat Exchangers (BHE) field design, as well as the pyroclasts layers effect on its performance, were calculated using finite element code FEFLOW [21], which takes into account the conductive and advective heat transport in the subsurface. A three-dimensional (3D) model was constructed, with an extension of 409.58 m × 477.31 m × 278.8 m (Figure 2). It was dimensioned to provide a simulation period of 30 years without border effects. A uniform 20.27 ºC initial temperature was assigned to the whole domain, representing the undisturbed ground temperature. The 12 BHEs field was implemented in the model via a widely non-sequential (essentially non-iterative) coupling strategy for the BHE and porous medium discretization, including relationships for thermal resistances and capacities of BHE. Pipe-to-grout thermal transfer with multiple grout points for a single U-shape BHE were considered [22]. A transient regime was adopted for the heat transport problem. No other heat transfer boundary conditions were considered in the model. Thermal parameterization of the domain included a package of basaltic lava flows, and intercalated pyroclasts with a thickness of 20–60 m (Figure 2). A thermal conductivity of 2.0 and 0.5 W·m−1·K−1 were considered for massive basalts and pyroclasts, respectively. The volumetric heat capacity of massive basalts and pyroclasts was 2.0·× 106 and 0.5 ×·106 J·m−3·K−1, respectively. To assess the impact of intercalated pyroclastic layers on the performance of the BHEs, a secondary scenario was examined. In this scenario, the subsurface was assumed to consist solely of massive basalts with homogeneous properties. A simulation spanning 30 years was conducted to analyze the input temperature within the BHEs, aiming to sustain a continuous dissipation of 29.6 kWth, which represents the cooling power required by the system.

Figure 2. (A) The finite element mesh created for the geothermal heat transport model is depicted. Pyroclasts intercalated within basaltic lava flows are highlighted in blue, while non-highlighted materials predominantly consist of basalts. (B) A close-up view provides detailed insight into the array of 12 Borehole Heat Exchangers (BHEs), each with a depth of 109 m.

Figure 2. (A) The finite element mesh created for the geothermal heat transport model is depicted. Pyroclasts intercalated within basaltic lava flows are highlighted in blue, while non-highlighted materials predominantly consist of basalts. (B) A close-up view provides detailed insight into the array of 12 Borehole Heat Exchangers (BHEs), each with a depth of 109 m.

The energy needed to produce wine is mainly due to lighting, grape processing, wine pumping filtration and mixing, bottling, thermal conditioning, sterilisation and cleaning, wine moving machinery and miscellaneous auxiliary processes (Smyth & Nesbitt, 2014) [23]. The calculations performed that demonstrated that cold water requirements are greater than hot water ones, so that refrigeration is s daily necessity in the facility. Therefore, a reversible heat pump was selected, as this system allows the heat extracted by the cooling system to be partly used to produce hot water instead of being sent all the way back into the ground. The selected pump has an exhaust heat recovery system allowing the production of domestic hot water in cooling mode. Consequently, part of the heat extracted from the facilities by the system is transferred to a hot water tank and partly discharged into the ground through geothermal probes. The generation of hot water, when the heat pump is in cooling mode, is 15 kW, and is able to provide a temperature of 60 ºC, which is enough to satisfy the hot water needs of the winery.

Since there were no pre-existent wells around the winery, it was decided to opt for a closed geothermal circuit with vertical probes. To build the probes, it was crucial to assess the geology of the area, which is made up of a set of old casts and interspersed pyroclasts, up to a thickness of 20–60 m. There are very massive and powerful basaltic casts, with a highly developed columnar disjunction and visible thicknesses of 10 to 20 m. The GHP installation costs depend on the reservoir depth, its applications, the type of technology to be used and the maintenance required [24,25].

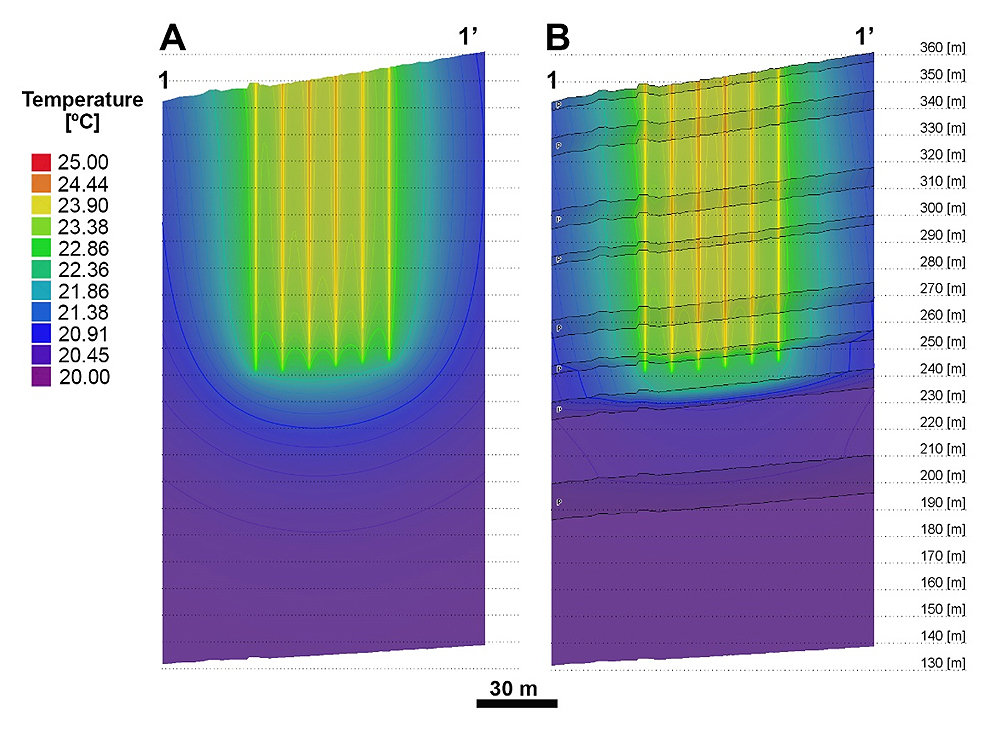

Performance analysis of BHE exchangers results are shown in Figure 3 and Figure 4. Finite element simulations showed a clear effect of the pyroclasts’ low thermal conductivity, as they increased the thermal impact area in the BHEs surroundings. This effect is the result of a reduced capability of the terrain to dissipate heat. Although both scenarios had the same input temperatures and constant flow rate through the BHEs, the returning temperature of the heat-carrier fluid was higher when pyroclast layers were considered (scenario B), thus reducing the energy transfer rate to the terrain. The model results indicated a 20.1% reduction in the energy transfer capabilities and, thus, the need to add an additional depth of 21.9 m to each BHE, going from the initial theoretical 87 m to the final 109 m deep finally adopted. With this changes, the 12 BHE raised their heat power dissipation capacity from 23.6 to 29.6 kWh. This adaptation to pyroclastic layers allowed to meet the specific cooling requirements of a winery located in volcanic geological profiles (active volcanic islands).

Figure 4. Cross-section 1-1’ (refer to Figure 3A) illustrates the vertical profile of ground temperature in the vicinity of the 12-Borehole Heat Exchanger (BHE) field. (A) Represents the scenario of massive homogeneous basalts, while (B) depicts the scenario of basaltic lava flows intercalated with layers of pyroclasts. The pyroclastic layers (P) are depicted by black-darkened polygons.

Figure 4. Cross-section 1-1’ (refer to Figure 3A) illustrates the vertical profile of ground temperature in the vicinity of the 12-Borehole Heat Exchanger (BHE) field. (A) Represents the scenario of massive homogeneous basalts, while (B) depicts the scenario of basaltic lava flows intercalated with layers of pyroclasts. The pyroclastic layers (P) are depicted by black-darkened polygons.

Low-temperature geothermal facilities applied to buildings are cost-effective and able to adapt to the thermal needs of different facilities types and uses. Low enthalpy projects are viable due to a wide array of reasons. First, they allow a lower dependence on primary energy, which is one of the objectives sought when using renewable energies. Second, geothermal energy is clean energy, as it reduces CO2 emissions to the atmosphere, and is very efficient due to its inexhaustible nature. It is also a good alternative to conventional heating systems and residential air conditioning. Third, monitoring inside the facility using an intelligent control system makes it much more profitable in terms of system maintenance and more energy efficient (as correct maintenance leads to greater energy efficiency, less environmental impact, breakdown and cost reduction, and a longer life for the installation). Geological characteristics unique to active volcanic islands highlight the need to identify and take into account the presence of highly porous pyroclastic layers for the design of geothermal BHEs. These layers can significantly impact drilling depths, potentially needing to reach up to 262.8 m. This adverse effect on geothermal heat exchangers adds an extra challenge to the development of shallow geothermal energy in volcanic islands, together with the already higher drilling costs compared to drilling in mainland areas. However, it is essential to note that shallow geothermal energy remains the most efficient electrification technology for the thermal sector. This research contributes to the reduction of uncertainties and aids in preventing suboptimal practices in the implementation of geothermal systems in active volcanic island environments.

The dataset of the study is available from the authors upon reasonable request.

Conceptualization: GLP, Validation: JCS, Software: SGC, Methodology: CE, Resources: AGG, Data curation: JRM, Writing—original draft preparation: NCP.

The authors declare that there is no conflict of interest.

This research was supported by the SAGE4CAN project, which is funded by the Spanish Research Agency (Agencia Estatal de Investigación, AEI), project PID2020-114218RA-100. Samanta Gasco Cavero participates in collaborative endeavours with IGME, separate from her official duties within the Madrid Council.

Also, this research was partially supported by the European Union's Horizon 2020 Research and Innovation Program, Grant Number: 101037424.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22

23.

24.

25.

Gasco S, Pacheco GL, García-Gil A, Rodríguez-Martín J, Expósito C, Cruz-Pérez N, et al. The Effect of Pyroclasts in Geothermal Borehole Heat Exchangers Performance on the Volcanic Island of Lanzarote (Canary Islands, Spain). J Sustain Res. 2023;5(4):e230016. https://doi.org/10.20900/jsr20230016

Copyright © 2023 Hapres Co., Ltd. Privacy Policy | Terms and Conditions