Location: Home >> Detail

TOTAL VIEWS

J Sustain Res. 2025;7(2):e250041. https://doi.org/10.20900/jsr20250041

1 Department of Mechanical & Manufacturing Engineering, Faculty of Engineering, The University of the West Indies, St. Augustine Campus, St. Augustine 330912, Trinidad and Tobago

2 Department of Civil and Environmental Engineering, Faculty of Engineering, The University of the West Indies, St. Augustine Campus, St. Augustine 330912, Trinidad and Tobago

* Correspondence: Chris Maharaj.

This study examined the integration of crumb rubber (CR) into hot mix asphalt (HMA) using Trinidad Lake Asphalt (TLA) modified bitumen and the dry process, addressing a critical gap in sustainable road construction. Microwave pre-treatment of the CR was identified as the most suitable method for local application, contributing to reduced bitumen absorption. The research utilised locally sourced CR derived from end-of-life tyres, promoting sustainable practices and supporting circular economy principles. Initial mix design evaluations revealed that only the 0% and 1% CR mixes met acceptable criteria for air voids, voids in mineral aggregate, voids filled with bitumen, stability, and flow. These mixes were further subjected to Indirect Tensile Stiffness Modulus (ITSM), Tensile Strength Ratio (TSR), and Marshall Stability and Flow tests. The 1% CR mix demonstrated a 14.29% reduction in optimal bitumen content (OBC) compared to a similar study, while requiring 8.48% less bitumen than the 0% CR mix in this study, validating the efficacy of microwave pre-treatment in reducing bitumen absorption. Performance testing revealed strong moisture resistance, with TSR values exceeding 0.7. The 1% CR mix exhibited a TSR value 4.92% higher than the 0% CR mix, affirming its superior moisture damage resistance. However, lower-than-expected ITSM and Marshall Stability values may have been attributed to CR sizes, fibre content in the CR, and dry mix process. Despite these limitations, the findings affirm the potential of locally sourced CR to enhance the sustainability of HMA, reducing reliance on virgin aggregates. Future research should focus on refining mix designs and assessing long-term performance under tropical conditions to solidify CR modified asphalt pavement as a sustainable solution for infrastructure development. Additionally, further investigation is needed to isolate the individual and combined effects of the CR particle size used in this study versus microwave treatment on bitumen absorption.

Road infrastructure is vital to modern economies, supporting socio-economic development by enabling the movement of people and goods through accessible and sustainable routes [1]. As new roads are constructed to enhance connectivity and alleviate traffic congestion, environmental concerns also increase due to higher vehicle usage and the extraction of virgin aggregates [2,3]. In Trinidad and Tobago, vehicle numbers are estimated between 800,000 to 900,000, with over one million registered vehicles [4]. This underscores the need for environmentally responsible construction practices. Asphalt pavement, the most widely used road surface globally [5], is typically composed of HMA a blend of bitumen and aggregates that ensures flexibility and durability [6].

The rapid increase in vehicular traffic has led to a significant accumulation of End-of-Life (EOL) tyres, raising pressing environmental concerns [5]. In tropical climates, improving binder performance under high temperatures is essential. One solution is incorporating natural asphalt into bitumen, enhancing resistance to heat-induced pavement defects [7]. Natural asphalt is sourced from ground deposits, whereas refined bitumen is derived from crude oil distillation [8]. A sustainable engineering solution involves recycling these tyres into CR, a material increasingly used in pavement engineering, particularly in asphalt mixtures [6,7]. CR has been recognized for enhancing the mechanical performance and structural integrity of asphalt pavements, notably improving rutting resistance and overall durability [1,6].

CR is typically introduced into HMA through two primary methods: the wet and dry processes [9]. In the wet process, CR is blended with bitumen, partially replacing the binder, while in the dry process, it substitutes a portion of the aggregate [10]. While both approaches offer performance benefits, the dry method allows higher CR incorporation [10–12], contributing to sustainability goals. However, CR absorbs lighter fractions of bitumen, such as saturates and aromatics, which reduces effective binder content and compromises cohesion and durability [10,13,14]. Controlling bitumen absorption is thus a critical factor in achieving desired performance outcomes.

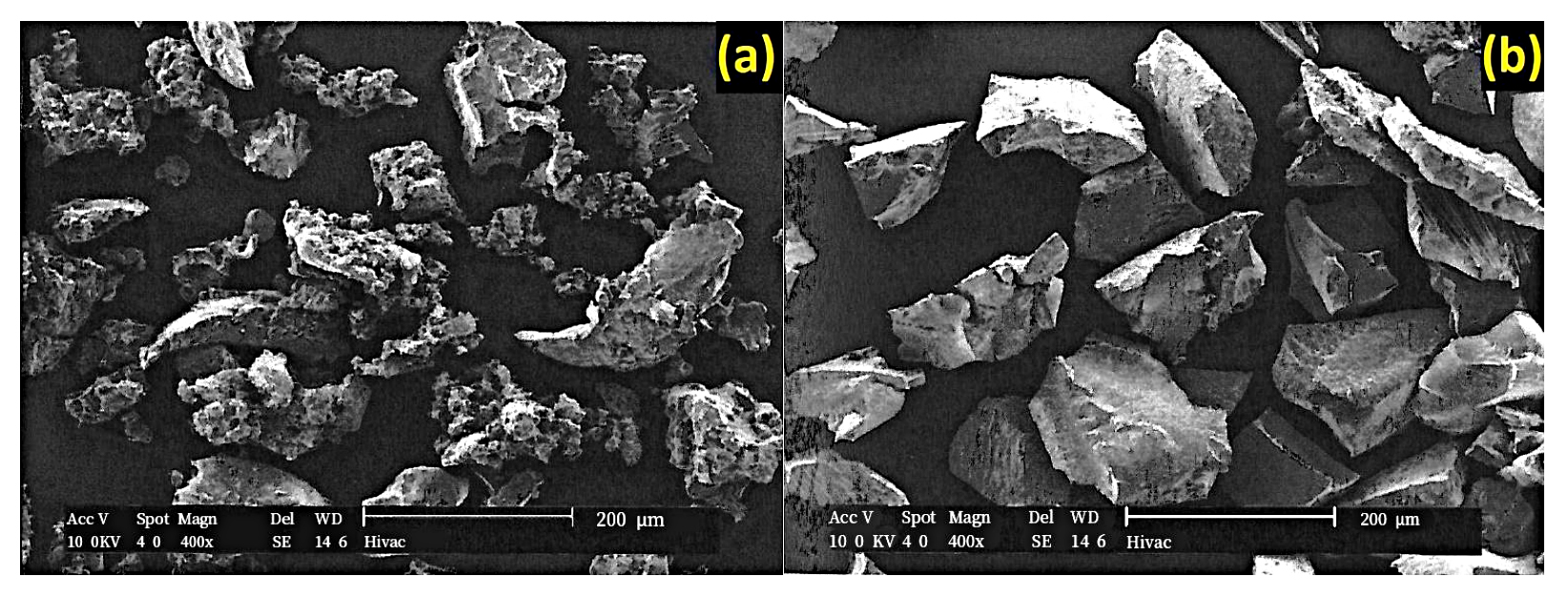

The physical morphology of CR determined by processing techniques such as ambient, cryogenic, or wet grinding, affects its interaction with the binder. Cryogenic processing yields smoother CR particles, while ambient grinding results in rougher, sponge-like surfaces (Figure 1) [6,15,16]. Surface texture significantly influences binder–rubber adhesion, which plays a vital role in the mechanical behaviour and durability of asphalt mixtures. Morphology can be further optimized through chemical or thermal pre-treatment methods. For instance, Badughaish et al. [17] showed that potassium permanganate (KMnO₄) and distilled water treatments increased CR porosity and surface roughness, thereby improving interaction with bitumen and overall mix performance [14,16].

Figure 1. CR composition due to processing methods: (a) Ambient, (b) Cryogenic [18].

Figure 1. CR composition due to processing methods: (a) Ambient, (b) Cryogenic [18].

Beyond morphology, CR particle size is a crucial design parameter in pavement performance modelling. Finer CR particles (<0.6 mm) have been shown to enhance rutting resistance and compaction efficiency, resulting in lower air void content and improved fatigue life [19]. Tan et al. [10] found that finer CR particles minimize binder absorption and swelling, promoting better volumetric properties, including voids in mineral aggregate (VMA) and mixture stability. Conversely, coarser particles tend to absorb more binder, leading to swelling and reduced stiffness. This insight aligns with pavement design principles where mechanical stability and deformation resistance are paramount. The optimal CR content in HMA remains a subject of parametric sensitivity analysis across studies. Several researchers [10,11,20,21] have identified 1–2% CR as the effective range for enhancing high-temperature performance, moisture resistance, and structural stability. For instance, Eltwati et al. [20] and Ma et al. [22] reported superior performance at 2% CR, while Tan et al. [10] recommended 1% for dense-graded HMA. However, variations in mix design, aggregate gradation, and filler types affect optimal dosage. Kamarudin et al. [23] found that as little as 0.75% pre-treated CR could deliver significant benefits, suggesting that optimal CR dosage may vary depending on specific mix conditions and material properties.

Bitumen absorption by CR remains a challenge, altering rheological properties such as softening point, ductility, and penetration value [24,25]. These changes affect viscoelastic behavior, especially at high service temperatures. CR swelling, which increases air voids and reduces compacted density, is influenced by the penetration grade of bitumen and the size of CR particles [14,23–25]. Smaller CR particles reach equilibrium faster, modifying viscosity, while larger ones tend to degrade but may enhance stiffness at high temperatures. This trade-off demands robust multi-objective optimization during mix design. To mitigate bitumen absorption and improve CR-binder compatibility, various pre-treatment techniques, both physical and chemical have been studied. These include microwave irradiation, oxidation, devulcanization, and pre-swelling using waste oils [24,26]. In the local context of Trinidad and Tobago, accessible resources such as household microwaves, waste cooking oil (WCO), and waste motor oil (WMO) offer viable, low-cost CR treatment options. Microwave pre-treatment, using 800 W microwaves for 90s, has demonstrated improved CR swelling and reduced emissions [27,28]. Yin et al. [27] and Liang et al. [29] confirmed enhanced binder aging resistance, stiffness, and deformation resistance using microwave-treated CR. Despite promising results, Zhang et al. [30] emphasized the need for further research to validate its long-term effects.

Feng et al. [31] explored WCO as a pre-swelling medium by heating CR and soaking it in WCO (3:1 mass ratio) for 72 h, leading to improved low-temperature performance and binder compatibility. Ruikun et al. [32] confirmed these benefits using different WCO:CR ratios. However, in Trinidad, WCO availability is limited due to export demands by companies like Ecoimpact, which processes WCO for biofuel. This restricts large-scale local use in asphalt applications. Alternatively, Liu et al. [33] investigated WMO for CR pre-treatment using a microwave and the wet process. They reported improved durability, mechanical strength, and better CR dispersion. WMO also enhanced binder rheology and thermal stability. In Trinidad, WMO is collected by companies such as Oil Mop Environmental Services Limited (OMES) for reprocessing, demonstrating its potential for sustainable application in various industrial processes.

Natural Asphalt in Asphalt MixturesNatural asphalt is widely used as a performance-enhancing additive in asphalt mixtures, offering improved resistance to high temperatures and deformation [7]. Unlike refined bitumen, which is produced through the distillation of crude oil, natural asphalt is derived from ground deposits and is valued for its inherent hardness and thermal stability [8]. Its incorporation into bituminous binders has been explored internationally to enhance pavement performance. Trinidad lake asphalt, a naturally occurring asphalt sourced from the world’s largest known deposit in Trinidad. TLA is typically blended with petroleum-derived bitumen and has been used in road construction, both locally and internationally, due to its compatibility and availability [34–36].

The application of TLA in asphalt mixtures has been shown to significantly improve high-temperature performance, rutting resistance, and long-term ageing properties [35–37]. Xu et al [36] recommended the use of TLA-modified binders in hot climates, although studies have also reported a reduction in low-temperature flexibility, likely due to increased stiffness [34,36]. Comparative assessments by Meng et al. [38] found TLA to outperform other additives such as SBS and Gilsonite in resisting rutting and cracking, albeit with some increased brittleness. Zhou et al. [39] reported that TLA enhanced rutting resistance in both aged and virgin binders but reduced fatigue resistance, attributing this to altered asphaltene–maltene interactions that affect binder structure. Despite these trade-offs, TLA’s proven performance, ease of integration with existing systems, and strong local relevance position it as a sustainable and practical modifier for asphalt pavement in tropical climates.

Enhancing Pavement Performance through CR Modification and Performance TestingThe mechanical properties of asphalt pavement are crucial to its durability and long-term performance. Performance testing helps evaluate the effects of pre-treated CR and determine its optimal content in asphalt mixes. Since the interaction between pre-treated CR and bitumen influences mechanical behaviour, understanding this relationship is especially important in hot, traffic-congested regions [14,23,40]. CR particle size is a key factor, as it affects air void content an important parameter for pavement performance [10]. While CR can enhance rutting resistance, Almusawi et al. [41] found that high CR content increases air voids after compaction, which can compromise durability. Finer CR particles help reduce this effect by decreasing void content and bitumen absorption, thus leaving more bitumen to fill remaining voids [10,40,41]. Other studies [10,19,42] confirmed that CR particles smaller than 0.6 mm perform better in terms of compaction, rutting resistance, and overall mechanical properties. In assessing performance, tests such as ITSM, TSR, and Marshall Stability and Flow are critical. ITSM evaluates the pavement's stiffness under stress, TSR gauges moisture damage resistance, and Marshall tests assess deformation resistance all vital for mix optimization under local conditions.

Research ObjectivesOverall, the literature shows that CR modification especially when combined with pre-treatment methods like microwave activation or WCO can significantly enhance asphalt mix performance. These methods improve CR–bitumen compatibility and help address common issues like absorption and swelling. When paired with robust performance testing (ITSM, TSR, Marshall), they provide a solid foundation for developing durable, climate-resilient, and sustainable pavement solutions. Presently, there is limited research exploring the combined application of TLA modified bitumen and CR within HMA using the dry process. Research on reducing bitumen absorption by CR in this context is also sparse, especially with regard to TLA modified bitumen. Bridging this research gap holds significant promise, as it not only contributes to minimising the environmental impact of EOL tyres but also reduces the quantity of excavated virgin aggregate needed for construction, all while enhancing the performance of asphalt pavement. The use of locally sourced CR from a newly established plant in Trinidad and Tobago further underscores this study’s potential to contribute to sustainable practices by leveraging accessible materials and local infrastructure. This study seeks to improve the sustainability of asphalt pavement construction by investigating methods to enhance CR interaction in a TLA-HMA mixture using the dry process. Objectives include exploring techniques for mitigating CR bitumen absorption and evaluating mechanical properties through performance testing. The inclusion of CR from EOL tyres into construction materials like asphalt pavement offers a promising solution to the environmental challenges posed by tyre waste. This sustainable approach not only strengthens asphalt pavements but also addresses the pressing issue of waste management, aligning with a more environmentally conscious future.

The type of natural coarse aggregate (19 mm, 12.5 mm, 9.5 mm) used in the HMA was blue limestone, while the natural fine aggregate was a combination of a 1:1 ratio of sharp sand and limestone dust. The CR produced from EOL tyres was obtained from the recently established plant operated by the Caribbean Industrial Research Institute (CARIRI). The CR used in this study consisted of particles with sizes ≤0.6 mm. Figure 2 shows the difference in the aggregates, Figure 3 indicates the gradation curves for different types of aggregates, while Table 1 shows the aggregates physical properties. The bitumen used in this study was a blend of refined bitumen and TLA, conforming to ASTM D2397. This blend was sourced from Lake Asphalt of Trinidad and Tobago (1978) Limited. The properties of the bitumen are presented in Table 2.

CR Pre-Treatment MethodAmong the available options of microwave, WCO, and WMO pre-treatment methods, microwave pre-treatment was selected as the most viable choice for this study. The limited availability of WCO, due to contracts between local restaurants and Ecoimpact, made it impractical for large-scale pavement applications. Similarly, the recycling and reuse of WMO by local companies restricted its availability for use in CR pre-treatment. In contrast, microwave pre-treatment was well-supported by research and had been shown to improve rutting resistance and high-temperature performance, qualities essential for asphalt pavement applications in tropical climates. In addition to the performance improvements, it can also reduce bitumen absorption though its ability to partially devulcanize the CR [43]. For these reasons, microwave pre-treatment was chosen as the optimal approach for laboratory testing and potential future applications under local conditions. The CR was microwaved for 90 s in an 800 W microwave in batches of weight 60 g.

Mixture Design and Sample PreparationDense graded HMA mixtures were firstly manufactured with both conventional aggregates and CR following the Marshall mixture design procedures. Aggregate blends were made according to the wearing course mix design as shown in Figure 4. These blends were preheated to the mixing temperature of 140 °C for approximately 16 h in a convection oven. Immediately after removal from the oven, CR was added to the aggregate blends in percentages of 0%, 1%, 3% and 5%. The CR was incorporated into the HMA by weight percentage using the dry process, as this method allows for a higher CR content in the HMA. Immediately after the bitumen was added in the required percentage. Multiple aggregate blends for each percentage of CR were made to accommodate the testing of different bitumen contents ranging from 4.5% to 6.5% and increasing in 0.5%.

The aggregate blends with the CR and bitumen percentages were then placed into a heavy duty digital thermostatic control drum mixer that was preheated to the mixing temperature of 150 °C. The HMA containing 0% CR was mixed for 180 s as this was the control mix. The HMA that contained 1%, 3% and 5% CR was mixed for 300 s. Once the mixing was complete, the test samples were compacted in accordance with ASTM D6926. The Marshall mix design technique was used to determine the OBC for all mix types. When the OBC was obtained a total of 94 specimens were prepared for further performance testing.

Performance EvaluationMarshall Stability testing is essential for assessing compacted HMA’s mechanical properties. The test was used to evaluate the mixture resistance to structural failure, elastic and plastic behaviour. These tests adhere to ASTM D6927-22 standards, ensuring consistency and reliability in the evaluation process [20,40,41,44]. Some samples were subjected to the ITSM test. This procedure evaluates the elastic resilient modulus stiffness of HMA and adhere to the BS EN 12697-26 standard. Stiffness is defined as the ratio of the applied stress to the recoverable strain, which directly influences the pavement's resistance to traffic loads and potential damage. This test is essential for predicting how the compacted HMA will perform under different conditions, especially regarding its durability [45,46].

The TSR test method was used to evaluate the moisture susceptibility of compacted HMA by comparing the Indirect Tensile Strengths (ITS) of wet (conditioned) and dry (unconditioned) specimens. This method provides insights into how moisture affects the bond between the bitumen and aggregates, a key factor in assessing long-term pavement durability. The test is conducted according to the BS EN 12697-23 standard for ITS, The TSR value is the ratio of ITS of conditioned specimen and the unconditioned specimen [47].

The flow diagram shown in Figure 5, outlined the experimental process, including material preparation, CR pre-treatment, Marshall Mix Design, and performance evaluation. Each step, from selecting materials to final performance assessments, ensured a systematic approach to determining the optimal CR pre-treatment and HMA properties. The study mix limits will be guided by data from Leon et al. [48] which provides crucial guidance on acceptable test value ranges for local asphalt mixes. This information was applied to evaluate the results obtained in this study, ensuring they meet the necessary standards for practical use in the country's specific conditions. By comparing the experimental results from this study with these established ranges, the design mix formulations for each CR percentage, can be accurately assessed for their potential implementation in local infrastructure projects.

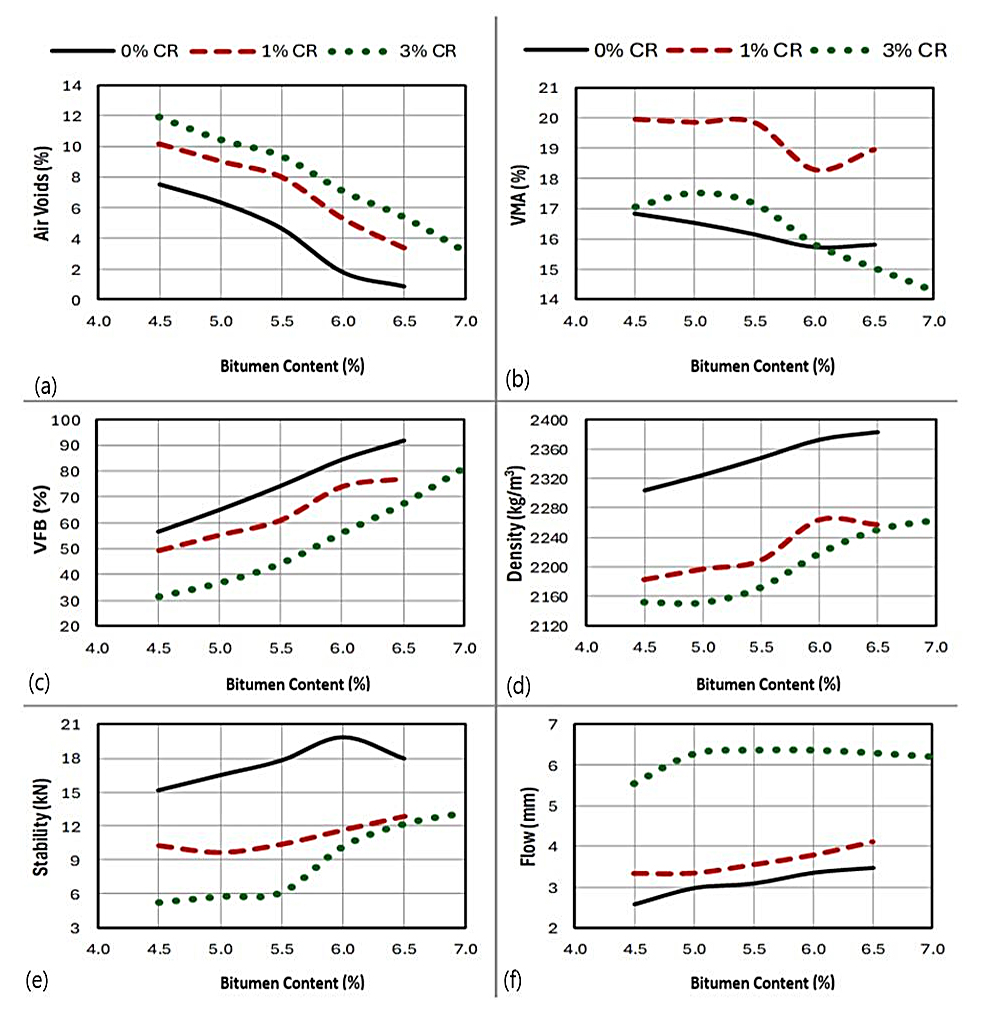

Figure 6 depicts the correlation between bitumen content and air voids across various CR percentages (0%, 1%, 3%, and 5%). For 0% and 1% CR mixtures, air voids remain within the permissible range (3–5%) at roughly 5.6–6.2% and 5.15–5.65% bitumen content, respectively. The equilibrium of bitumen and aggregate produces a denser composition with minimised air gaps, according to durability criteria. Nevertheless, the 3% and 5% CR mixtures exhibit significantly elevated air void percentages, beyond the permissible limits, potentially resulting in heightened moisture infiltration and deterioration of the pavement. This implies that these mixtures would fail to meet local acceptable criteria, namely regarding binder content within permissible limits and acceptable air void ranges. Furthermore, these mixtures would exhibit increased vulnerability to structural deficiencies, hence diminishing their overall efficacy and longevity. The 0% CR mixture regularly exhibits the highest density, reaching a maximum of 2406 kg/m³, signifying superior compaction. The 1% CR is closely associated with densities varying from 2268 to 2351 kg/m³. The 3% and 5% CR mixtures have markedly reduced densities. This indicates that increased CR concentration results in less compact and less dense mixtures, potentially impacting the pavement's strength and longevity.

The link between bitumen content and VMA for the same CR percentages is seen in the graph in Figure 7. A VMA value of 15% is considered acceptable. All blends show a small decrease in VMA values as bitumen content increases. Strong structural integrity is a result of effective bitumen distribution and aggregate packing, as indicated by the VMA range of 15% to 18% for the 0% and 1% CR mixes. The VMA levels of the 3% and 5% CR mixtures, however, are higher. This suggests that the aggregate structure of these blends is looser, which might result in decreased strength, heightened rutting susceptibility, and generally subpar performance under high traffic situations.

The voids filled in bitumen (VFB) versus bitumen content for different CR percentages is also shown in Figure 7. The VFB range of 70% to 80% is considered appropriate. In all combinations, the VFB increases as the bitumen content increases, indicating good binder dispersion within the aggregate structure. The 0% and 1% CR mixes fall within the permitted range of 5.65–6.1% and 5.15–5.6% bitumen content, which guarantees improved durability and moisture resistance. The VFB values for the 3% and 5% CR mixes, however, are considerably outside the permissible limit. This implies that these mixes do not sufficiently fill the aggregate spaces with binder, which results in decreased durability and cohesiveness and may eventually cause problems like cracking or early pavement breakdown.

The graph in Figure 8 illustrates the correlation between bitumen content and stability for varying CR percentages. As the bitumen content increases, the stability values of the 0% CR blend exhibit an upward trend, consistently remaining within the permissible stability range of greater than 8 kN. Conversely, the 1% CR blend exhibited a downward trend while maintaining a bitumen content within the acceptable range of 4.5% to 6.7%. This suggests that the mixture is stable and capable of efficiently withstanding the applied loads. Nevertheless, the stability of the 3% CR blend decreases significantly as the bitumen content increases. At a 4.5% bitumen content, the stability of the mix decreases from 18.6 kN to 10.2 kN at 6.5%, which is still within the acceptable range. The stability of the 5% CR mix is the lowest, with a value of less than 5 kN, which is significantly below the acceptable threshold. This implies that a higher CR content decreases the mix's overall stability, rendering it less capable of withstanding intense traffic volumes.

The flow values in Figure 8, which indicate the mix's capacity to deform under load, increase as the bitumen content increases in all CR mixes. The flow values are primarily maintained within the permissible range of 2 to 4 mm by the 0% CR mix. The 3% CR mix exhibits a comparable pattern; however, it marginally exceeds the upper limit of the acceptable range. The acceptable range is also maintained by the 1% CR mix; however, it is surpassed at bitumen contents exceeding 5.5%. Conversely, the 5% CR mix exhibits substantially higher flow values, surpassing 12 mm at a bitumen content of 6.5%, which is notably outside the acceptable range. This implies that pavement failure and rutting may occur as a consequence of excessive deformation caused by a higher CR content in response to traffic loading.

According to the results from the tested mix design formulations, only the HMA with 0% and 1% CR satisfied the required mechanical performance requirements for further assessment. The parameters for both mixtures conformed to acceptable thresholds for air voids, VMA, VFB, stability, and flow, rendering them appropriate for performance evaluation. Thus, these two mixtures were chosen for the ITSM, TSR, and Marshall Stability and Flow tests with 5.9% and 5.4% bitumen content, since they were determined to be their optimal binder contents. Performance testing was done to evaluate their appropriateness for pavement construction.

Optimum Mix Performance ReviewThe results of the Marshall Stability test (refer to Figure 9) for the two mixtures show notable variations in performance and variability. The 0% CR mix attained a stability of 8.9 kN, above Trinidad's minimal requirement of 8 kN, with a standard deviation of 1.39. The elevated standard deviation indicates a broader dispersion in the individual test results, reflecting a little reduced consistency in the performance of the mix. Conversely, the 1% CR mixture produced a stability of 5.2 kN, which did not meet the required threshold, and demonstrated a lower standard deviation of 0.57. The decreased standard deviation signifies more consistency in test findings for the 1% CR mix, despite a notable reduction in total strength.

The Marshall Flow test data indicated flow values of 0.13 inches (3.3 mm) for the 0% CR mix and 0.18 inches (4.6 mm) for the 1% CR mix. The 0% CR mix adheres to criteria of 2–4 mm, however the 1% CR mix surpasses this threshold. The increased flow seen in the 1% CR mixture suggests a possible decrease in stiffness and resistance to deformation, potentially affecting the pavement's long-term performance under substantial traffic loads. The standard deviation for the 0% CR mixture was 0.32, signifying a reduced level of variability in the flow measurements. Conversely, the 1% CR mix had a greater standard deviation of 2. The increased variability in the 1% CR mix indicates inconsistent behavior among the samples, possibly associated with the introduction of CR and its effect on the mix attributes. Notwithstanding the elevated flow value in the 1% CR mixture, the findings underscore the necessity of assessing both consistency and performance to guarantee the durability and appropriateness of HMA containing CR.

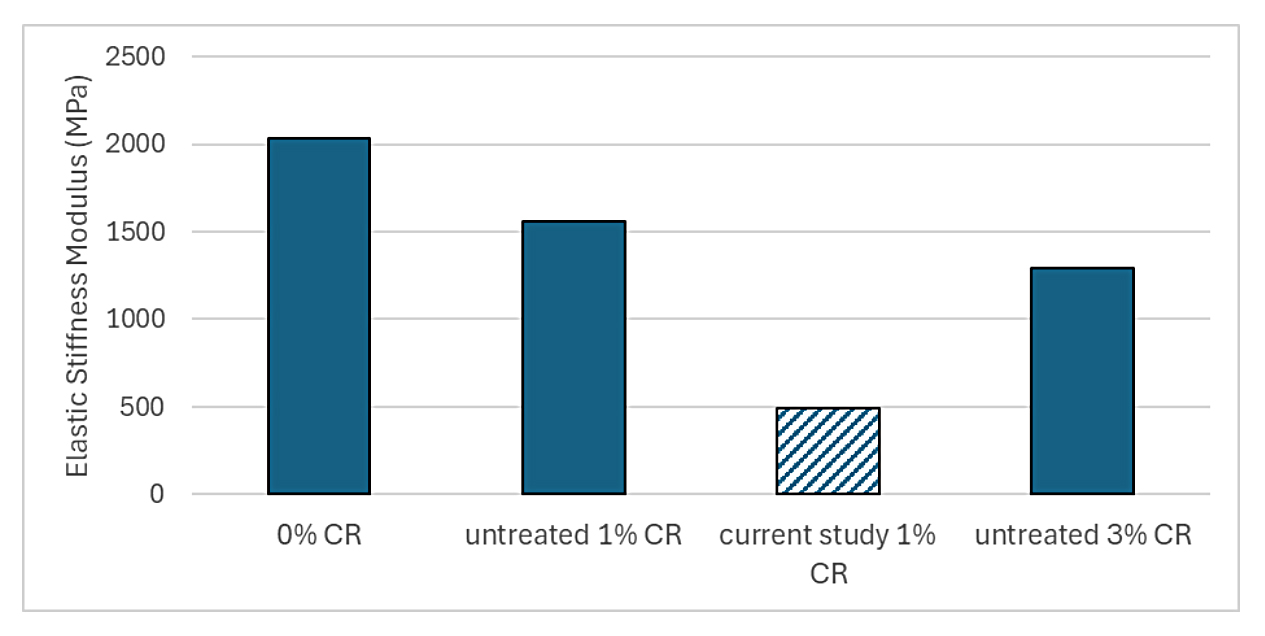

In the ITSM test illustrated in Figure 10, the 0% CR mixture demonstrated a stiffness modulus of 891.5 MPa, but the 1% CR mixture displayed a decreased stiffness of 495.17 MPa. Both results are below the permissible threshold of 1500 MPa, as specified in the performance standards by Leon et al. [48]. The notable decrease in stiffness with increasing CR content suggests that the incorporation of CR alters the elastic characteristics of the mixture, diminishing its overall stiffness and perhaps impacting its long-term structural performance under load. The standard deviation values, depicted as error bars in Figure 10, elucidate the variability of the data. The 0% CR mix displayed a larger standard deviation of 46.72 MPa, showing increased variability in stiffness values, whereas the 1% CR mix showed a lower standard deviation of 13.16 MPa, reflecting more uniform findings. This pattern corresponds with the actual results, indicating that the inclusion of CR seems to stabilise the stiffness measurements while reducing total stiffness. The decreased variability in the 1% CR mixture may suggest that the inclusion of CR fosters a more consistent and uniform material structure under testing circumstances. Nonetheless, the stiffness values for both mixtures fall short of the permitted threshold, highlighting the need for additional optimisation of the mix design to improve stiffness and meet the needed performance standards.

Comparison of Results with Similar StudiesThis study's mechanical and performance results were compared with findings from Leon et al. [49], which similarly examined the use of untreated CR in asphalt pavement utilising TLA 60/75 penetration class bitumen. Figure 11 illustrates the volumetric data summary of their findings. This study utilised pre-treated CR of ≤0.6 mm, whereas the prior research employed untreated CR ranging from 0.8 to 2.5 mm. Analysing the Marshall Mix Design formulations and performance outcomes reveals significant differences between this study and the research conducted by Leon et al. [49]. Both investigations indicated that the 0% and 1% CR mixtures met the allowable air void range of 3–5% within designated bitumen concentration levels. This study established OBCs of 5.9% and 5.4% for the 0% and 1% CR mixes, respectively, while untreated CR mixes exhibited OBCs of 5.6% and 6.3% for the same mixes. The results demonstrate a 5.36% rise in the OBC for the 0% CR mix and a 14.29% decrease in the OBC for the 1% CR mix relative to the untreated CR. This study also noted decreased air void percentages, consistent with other studies [10,41], which indicated that tiny CR particle sizes, particularly those under 1.18 mm, lead to a lower air void content than larger particle sizes. These findings together highlight the impact of CR particle size and pre-treatment methods on mix design characteristics, especially in minimising air gaps and maximising bitumen usage.

The density of the 1% CR mix in this investigation was consistently superior to that of the comparative study, as evidenced by the analysis of the mix design formulation findings. Furthermore, in contrast to this study, which failed to satisfy design criteria at 3% CR content, the prior study demonstrated that a greater bitumen percentage was necessary for their 3% CR mixture to fulfil air void specifications. This may result from alterations in the physical characteristics of the therapeutic CR.

The 0% CR mixture from both trials exhibited comparable ranges and trends for stability and flow values. This study revealed a declining stability trend for the 1% CR mix as bitumen concentration increased, in contrast to the rising tendency reported for untreated CR. The 1% treated CR mix had a somewhat higher upward trajectory in flow values with rising bitumen concentration relative to untreated CR. The identified parallels between the results of the 0% CR and 1% CR mixtures, formulated with treated and untreated CR, along with the attained acceptable ranges, warranted the choice of these mixtures for additional performance evaluation.

Figure 11. Summary of bitumen content versus volumteritc data from the study of Leon et al. [49]. (a) air Voids (b) VMA (c) VFB (d) density (e) stability (f) flow.

Figure 11. Summary of bitumen content versus volumteritc data from the study of Leon et al. [49]. (a) air Voids (b) VMA (c) VFB (d) density (e) stability (f) flow.

Comparative performance tests, utilising the ITSM and TSR assessments, were conducted for both untreated and treated CR mixtures. Figure 12 illustrates a significant reduction in ITSM values for both mix types when CR content increases. The treated CR mixture exhibited a stiffness modulus approximately 33% lower than that of the untreated CR mixes. These are presumably ascribed to the presence of CR fibres and mixing technique.

Figure 12. ITSM results for untreated [49] and treated CR.

Figure 12. ITSM results for untreated [49] and treated CR.

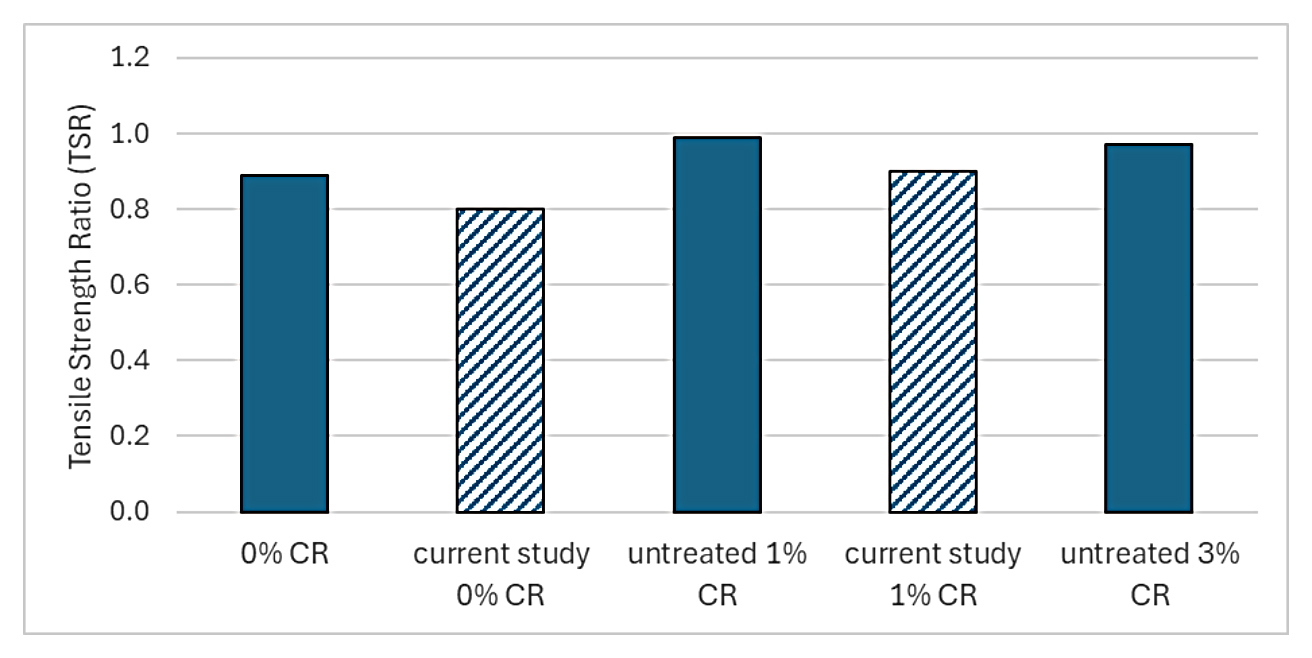

The TSR values for the treated CR, illustrated in Figure 13, surpassed the mandated threshold of 0.7, as delineated by the Asphalt Institute [44]. The 1% CR mix attained a TSR value 4.92% superior to the 0% CR mix, indicating robust resistance to moisture damage for both formulations. The results underscore the appropriateness of both mixtures for asphalt pavement construction, satisfying the requisite performance standards for moisture damage resistance. This further substantiates the assertion that CR can enhance the longevity and moisture resistance of asphalt mixtures.

Figure 13. TSR results for untreated [49] and treated CR.

Figure 13. TSR results for untreated [49] and treated CR.

A limitation was that the CR utilised in this investigation was obtained from CARIRI and included a very small amount of fibres from tyre fabric (refer to Figure 14), in contrast to the fibre-free CR supplied from the Netherlands in the work by Leon et al. [49]. The inclusion of fibres in the HMA may have negatively impacted the mix characteristics, perhaps leading to the diminished results obtained in the ITSM and Marshall Stability tests. This study has many principal drawbacks.

This study demonstrated the effective integration of microwave pre-treated CR into TLA modified HMA, presenting a sustainable and relevant approach to pavement enhancement. By addressing a major research gap, it confirmed the feasibility of using locally sourced CR from end-of-life tyres to support circular economy goals while improving pavement performance. Key findings showed that microwave pre-treatment of CR (≤0.6 mm) significantly reduced bitumen absorption, achieving a 14.29% reduction in optimum binder content and an 8.48% lower binder requirement in 1% CR mixes compared to 0% mixes. Both 0% and 1% CR blends met the Marshall Mix Design criteria and demonstrated strong moisture resistance, with the 1% CR mix showing a 4.92% higher TSR value.

Despite some challenges in mechanical performance, notably lower stiffness and stability due to preparation inconsistencies and CR material characteristics, the study confirmed the practicality and scalability of the method. The use of locally manufactured TLA and pre-treated CR, along with the availability of industrial microwave technology, supports commercial application. The approach offers cost savings by reducing aggregate and bitumen usage and yields environmental benefits such as reduced tyre waste and decreased reliance on virgin aggregates. This aligns well with sustainability goals and demonstrates the potential of CR-modified asphalt for tropical climates.

Future research should focus on optimising microwave treatment parameters, distinguishing the individual effects of particle size and pre-treatment on absorption, and improving specimen preparation techniques to enhance performance consistency. Quantification of the environmental benefits along with life cycle cost analysis of this method in comparison to others can also be considered in future work.

The dataset of the study is available from the authors upon reasonable request.

Conceptualization, CM and LL; Methodology, VR and LL; Software, VR and LL; Validation, CM, LL and VR; Formal Analysis, VR; Investigation, VR; Resources, CM and LL; Data Curation, VR; Writing—Original Draft Preparation, VR; Writing—Review & Editing, LL; Visualization, VR; Supervision, LL and CM; Project Administration, CM.

The authors declare that they have no conflicts of interest.

The authors would like to thank Rean Maharaj (The University of Trinidad and Tobago, UTT) for facilitating the acquisition of crumb rubber material from the Caribbean Industrial Research Institute (CARIRI), the staff of CARIRI and laboratory technician Marcus Britto (UWI) for his technical assistance during lab testing.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

38.

39.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

Ramroop V, Leon L, Maharaj C. Optimising crumb rubber integration in Hot Mix Asphalt. J Sustain Res. 2025;7(2):e250041. https://doi.org/10.20900/jsr20250041.

Copyright © Hapres Co., Ltd. Privacy Policy | Terms and Conditions