Location: Home >> Detail

TOTAL VIEWS

J Sustain Res. 2025;7(2):e250039. https://doi.org/10.20900/jsr20250039

1 Doctoral School of Regional and Business Administration Sciences, Széchenyi István University, Győr 9026, Hungary

2 Department of Education and Psychology, Apáczai Csere János Faculity of Pedagogy, Humanities and Social Sciences, Széchenyi István University, Győr 9026, Hungary

3 Department of Leadership and Marketing, Kautz Gyula Faculity of Economics, Széchenyi István University, Győr 9026, Hungary

* Correspondence: Márta Konczos Szombathelyi.

The purpose of the research is to review how artificial intelligence is integrated into the education of employees, emphasizing that the rapid application of artificial intelligence significantly affects the development of the workforce and the achievement of sustainability goals. The European Commission also continuously monitors changes in the field of digitization and artificial intelligence. Among other things, the European Union uses ESG (environmental, social, governance) aspects to measure sustainability performance, relying on domestic and international literature to reveal how education, investments and international cooperation can lead to social development and market competitiveness. As a research method, we use the analysis of annual reports, training and conference reports, company websites, and databases on corporate ESG commitment, employee development, and digitalization. Based on the decision of the European Commission, the continuous and rapid progress of the development of digitization and artificial intelligence is an issue to be monitored with reporting obligations. Analyzes of ESG reports help to understand the sustainability practices and environmental effects of a given organization, help to reveal social responsibility, interpret the company's long-term value creation potential and risks, measure and compare the sustainability performance of different companies and organizations. Analyzing ESG reports is key to promoting transparency and responsible business practices. Based on the developments, in addition to the economic results, the realization of the sustainability goals is becoming more and more tangible in the context of the ESG framework, the investigation of digitalization and artificial intelligence, as well as the labor market and education.

AI, artificial intelligence; ESG, environmental, social, governance; OECD, Organization for Economic Co-operation and Development; EU, European Union; SME, small and medium-sized enterprises; SDG, sustainable development goals; CSRD, corporate sustainability reporting directive; CSR, corporate social responsibility; EdTech, education technology; CAGR, compound annual growth rate; AR, augmented reality; VR, virtual reality; GDPR, general data protection regulation; MOOC, massive open online course; UNESCO, United Nations Educational, Scientific and Cultural Organization; ESRS, European Sustainability Reporting Standards; STEM, science, technology, engineering and mathematics; LLM, large language models; Cedefop, European Centre for the Development of Vocational Training

The study does not contain an in-depth analysis of a single company or event, nor does it focus exclusively on market and economic data. Rather, an exploratory scientific study combines data and perspectives from multiple sources, formulates research questions, draws conclusions, and makes suggestions for future research directions. The study examines companies’ compliance with social sustainability for the sake of future employees, in relation to digitized education and the application of artificial intelligence (AI). The rapid development of AI has a clear impact through the workforce factor on economic results and the realization of sustainability goals [1]. Due to the reporting obligations imposed by the decision of the European Commission, the realization of sustainability goals, digitalization and the application of AI have become factors designated for monitoring [2]. The perspectives of ESG as the means of measuring sustainability are increasingly prestigious evaluation criteria for investors and financial actors during risk analysis studies, and education for the sake of development, investments and international cooperation overall motivate the social development and market competitiveness [3–5]. Legislation is a central element in addition to financial capital, it is a base for changing lifestyles, increasing opportunities for equal opportunities, and combined with education, it has a significant impact on the development of the workforce [6]. Based on the expectations, the growth of educational investments and the transformation of traditional classrooms can be predicted, instead of the further training of the own workforce, retraining is manifested due to the shortened time interval, and international partnership can also help to catch up with the results achieved in the field of the knowledge-based society [7]. AI has emerged as a fundamental element of knowledge sharing, a chance to increase productivity and improve living standards [8].

The purpose of the study is to explore educational technology efforts embedded in sustainable and responsible AI applications used by companies, which represent a new path for future workers [9]. The study focuses on AI applications, as this technological development can provide a solution for further productivity growth, efficiency gains, and positive financial performance in the future. AI is now a systemic transformational force, identified as a catalyst for its profound labor market shaping impact, automation potential, personalized learning opportunities, efficiency-enhancing potential, and both risk and opportunity potential [10].

The Research method is based on analyses of annual reports, training and conference reports, company websites, and company ESG reports on employee development, digitalization and AI database analyzes [11–17]. The World Economic Forum, Eurostat, OECD, European Commission, UNESCO reports are complemented by statements from Audi, Bosch, IBM, BDO, Piac&Profit, Eurofound, Cedefop, Grand View Research, W3Tech, WebTechnology Surveys, typically covering the period 2019–2024. During the data collection, 18 company analyses, 12 international policy studies and 6 statistical databases were processed. The quantitative research approach was also assisted by database research and index research. The companies were selected based on size, sector and level of AI application in order to compare SMEs and large companies. Company reports can also be used for marketing purposes, so unfortunately, positive distortion of the data cannot be ruled out.

Based on the decision of the European Commission, digitalization and the use of AI are part of the reporting obligation of companies. The analysis of ESG reports is authoritative from the point of view of promoting transparency and responsible business practices, based on the developments, economic results and the realization of sustainability goals can be verified [18,19].

According to the 1987 report of the World Commission on Environment and Development, we must meet the needs of the present so that the next generation can their own needs. Based on this, the companies are compared objectively not from a financial and economic point of view, but from a sustainability point of view [20]. In 2015, the basic idea of the United Nations was added to the objectives of the European Union (EU) to be achieved by 2030 through the formulation of 17 sustainable development goals, together with the discussion of the issues of innovation, equal opportunities, job creation and education, the universality of “leaving no one behind” following its principle [18,21,22].

Based on Hungarian surveys, 83% of the surveyed companies claim that ESG will be important to them because of their reputation and expectations. 40% of the respondents would spend more, 50% would spend the same amount. Energy efficiency appears as the most frequented area (77%), in the case of SMEs, employee welfare, education, training and human rights are more prominent [23]. Solution diversities can provide an opportunity to avoid the homogenizing effect of institutional pressure on organizations [24].

In order to strengthen environmental awareness, based on the EU’s corporate sustainability reporting directive (CSRD), since January 2023, companies have been obliged to publish and report on the fulfillment of the standards based on reporting standards (European Sustainable Reporting Standards—ESRS) [25]. The reporting of non-financial information applies to all large companies and SMEs present in the markets, and supports the measures of the European Green Deal aimed at overcoming the climate crisis [15,26]. Corporate social responsibility (CSR) can generate decisive advantages for collaborators due to competitiveness. Based on the 2011 CSR strategy of the European Commission, cooperation is integrated into the basic strategies in social, environmental, ethical, human rights and consumer issues [27]. CSR practices can become suitable for raising the company’s reputation, attracting high-quality workforce and young talents, so organizations should pay special attention to this area [28].

Throughout history, the acceptance of new technologies, innovation, and the acquisition of new knowledge have always appeared as defining issues, which is how the issue of education was included among the 17 sustainability goals [29]. Responsible educational technology steps include the development of educational systems, the search and recognition of possible learning bases, and their transmission to students [30]. Sustainable and responsible educational technology efforts and AI work together effectively for the benefit of the workforce of the future. According to Bill Gates’ forecast, AI will induce significant changes even in everyday life within five years, but the IMF is concerned about the rapid evolution of AI, according to which approximately 40% of jobs may be affected by the extremely rapid development. It is clear that successful economies cannot exist without the widespread diffusion of digital capabilities. According to the founder of Microsoft, similar to the increase in agricultural productivity in the 1900s, AI can represent a chance to improve the standard of living, also for education, it can help remedy the shortage of teachers, it can start the process of realizing equal opportunities, but in the opinion of the doubters, it contributes even more to the increase of inequalities [31,32].

Research questions: What opportunities can digitalization bring to achieve sustainability goals? How do the labor market and education respond to this AI breakthrough? What impact does AI-based educational technology have on the skill level of employees? How sustainability is reflected in educational technology ESG reports? What factors influence the success of AI implementation in labor market-oriented education [11,12]?

A mixed methodological approach was applied during the research, combining qualitative and quantitative analysis techniques. A multi-stage criteria system was followed when analyzing the data sources. Regarding the relevance of the study, only company websites that are directly related to the topics of artificial intelligence, educational technology, ESG, and the labor market were examined. In terms of temporal validity, the analyzed documents originate from the period 2019–2024, thus providing an up-to-date picture of current trends. From a geographical perspective, the sources focus primarily on Europe, including Hungary, Germany, and the Nordic countries, but international comparisons were also made when examining OECD, UNESCO, and EU documents. We used two basic theoretical models for the analytical framework. The TAM (Technology Acceptance Model) was applied to examine the application of AI in education, with particular attention to the factors influencing acceptance (usefulness, usability, attitude), while SDG4 goal (Quality Education) was used to measure the contribution to the sustainable development goals. In order to ensure methodological rigor in data analysis, triangulation and comparison of multiple types of data sources were carried out when examining statistics from international organizations, corporate ESG reports, market research studies, and academic articles. Index-based analysis was performed to compare ESG performances. We applied filtered database analysis based on structured data collection tables, in which we used key indicators, such as the extent of education investments, the level of AI use, and digital skills development strategies. We also took into account the marketing biases of corporate reports and the reliability limitations of publicly available sources.

An overview of sustainable and responsible educational technology efforts with the application of AI research for the workers of the future reveals the most important educational technology and labor market opportunities and results in order to realize them. As a market-leading solution in the field of education, the study discusses the opportunities offered by products associated with cloud services, machine learning and natural language processing, the implementations are completed with the help of cooperative learning and healthy collaboration. The exploration of educational technology innovations is justified by the intense industry competition, where the strengthening of traditional education with the position of distance education, the knowledge of emerging content languages, and the use of AI position the chances of competitiveness to a significantly higher level. The labor market and education represent a common line of sustainability, in which the most dynamically growing elements are technology, digitization and sustainability. How would companies change their ESG spending in the future? The future of work is the acquisition of new technologies, the correction of expected basic skills through education, lifelong learning, improving the employment rate of young people, and the practical application of AI. The explosive expansion of the study’s research area means research limitations, so data is not yet available in some areas. The findings of mixed-method research are valid within the time interval of the research and require continuous updating, as AI, digitalization, and educational technology are rapidly changing fields. However, the conclusions drawn from the available data are useful, especially for identifying trends and defining primary frameworks. The study communicates these limitations transparently, which increases its scientific credibility. The study analyzes the introduction of AI in the educational context using the Technology Acceptance Model (TAM) and the SDG framework. In addition to the government reports, the data of the educational technology studies are independent technological reports of the service providers Grand View Research, W3Techs, Web Technology Surveys, International Labor Organization, and BDO Hungary, secondary sources are other educational technology and labor market documents and publications. The collected data were explored to identify educational technology and labor market trends and opportunities. The formulation of the market, the normalization of the data, and the data representation were made only based on validated data. The purpose of sharing the reports is to understand the dynamics of the educational technology and labor market and global market forecasts. The individual regional prospects required a short-term, up to 2030, and long-term forecast interpretation, primarily compared to the AI and sustainability segment prospects. The limited database of reports may result in a percentage deviation of the results, but it is suitable for detecting market trends. The validity of the trends is limited at the time of writing the study; the data require continuous updating in case of further research. Although the limited data, geographical and organizational limitations of the research require future expansion of the research, even in its current state it can serve as a basis for comparison in an international context. Due to the broad outlook, triangulation was applied by involving scientific and policy sources (Figure 1).

Answering the research question, the first one is: What opportunities can digitalization bring to achieve sustainability goals? In order to eliminate inequalities, the 2030 development framework tries to use all innovation tools to achieve the 17 development goals. In order to achieve the goals, lifelong learning is necessary for the individual, which will become available in the future with new educational technology solutions, e-books, micro-training, intelligent classroom training and other developments that are still in their infancy [3]. Innovation tools pervade the examined modernized education system and changes in the labor market, their development is also supported by official follow-up reports [33,34]. The possible distortion of the results of the empirical research, which is the basis of the study, stems from the depth of immersion and the limitations of data availability, so the reference to various reports serves to illuminate and strengthen the data in several directions. The fourth Development Goal, the process of realizing quality education, is supported by market expansion in the field of education, the appearance of typically North American development-led digital classrooms, and the latest game-based learning [9].

AI has already appeared in the field of personalized education and catch-up. By using quality educational basic data, it is able to provide assistance in the segment of education and the labor market connection and in order to achieve sustainability goals. The use of this support significantly affects the reputation and economic results of the given company, especially in the case of SMEs, the issue of education and the appropriate fulfillment of employee expectations is emphasized [23]. Based on the summary report of Cedofop [7], the joint work of vocational training, quality education, and educational technology developers generates catch-up in the knowledge-based society. According to the report of the World Economic Forum [35], the use of AI in the relationship between workplaces and the future of work is the key to increasing efficiency and competitiveness, as it is suitable, among other things, for the immediate sharing of technological knowledge. From the corporate reports of BDO, Audi Hungaria, IBM and NOKIA, it is possible to report on already implemented ESG steps and digitalization experiences, in which the importance of new essential employee skills, retraining, innovations, and the injection of the industrial application of AI with conditions can be seen [13,16,23,26].

In Europe, the evaluation of the workplace is an extremely important workplace expectation. The emergence of AI also significantly influenced the need for workplace stability. With the fourth industrial revolution, the direction of automation, the application of AI, new types of work appear, the rapid acquisition of which can be achieved with quality education, adaptability, a positive employee attitude, and retraining. AI still poses certain risks for the industrial environment, it needs further development, but it can also serve as a future solution to labor shortages. European Commission reports [15,36–38] report on EU ESG activities, steps taken in ESG ratings, reveal a coordinated plan for artificial intelligence, and convey a strategy for the transition to a sustainable economy. The results show that training platforms integrated with AI significantly support lifelong learning and corporate tracking of ESG objectives [39]. The W3Techs database, as a reliable source of information independent of service providers, presents us with a new emerging order of server usage, in which the leading role of English is not threatened now, but in addition to Spanish, German and Japanese, Russian and French also appear as content languages of increasing importance [40]. Many corporate ESG reports paint an overly optimistic picture of AI integration in education and retraining. These reports often emphasize innovation and productivity while neglecting ethical and equal opportunities challenges, or even practical application challenges, while current OECD and UNESCO reports highlight digital divides, algorithmic biases, and access barriers in low-income regions. These divergent realities highlight the gap between corporate ambitions and actual readiness.

Education TechnologyHow do the labor market and education respond to this AI breakthrough? What factors influence the success of AI implementation in labor market-oriented education? In the near future, EdTech (education technology) will undergo a complete transformation under the influence of AI, skills and competencies essential for the labor market will change [41]. Its success precludes short-term thinking during digitization processes, cooperative cooperation and a unified collaborative intention are emphasized expectations [42]. Among the market-leading solutions in the education technology of the future are products associated with cloud services, machine learning, and natural language processing [43].

Learning the benefits of flexibility, digital routine, personalized, motivating education, and group, cooperative learning is justified. We need transformative competences and the ability to compromise. In a knowledge-based economy, the acceptance of lifelong learning, even with the use of micro training, is essential for systemic thinking [44].

Cloud services, machine learning and natural language processing are becoming the number one application among the tools that support education, and accordingly, a vigorous increase in value can be forecast in the field of the educational technology market. The market worth 123.40 billion dollars in 2022 and 142.37 billion dollars in 2023 is expected to grow at a compound annual growth rate (CAGR) of 13.6% between 2023–2030 and reach 348.41 billion dollars by 2030 [45].

The popularity of e-books is also increasing, as they are available anywhere, can be translated into different languages, and the possibility of tutoring online is becoming more and more popular [46]. The Texthelp Ltd.’s new development result—documents available in OrbitNote-pdf format with voice notes, also available for the visually impaired—represents an opportunity to create equal opportunities [32].

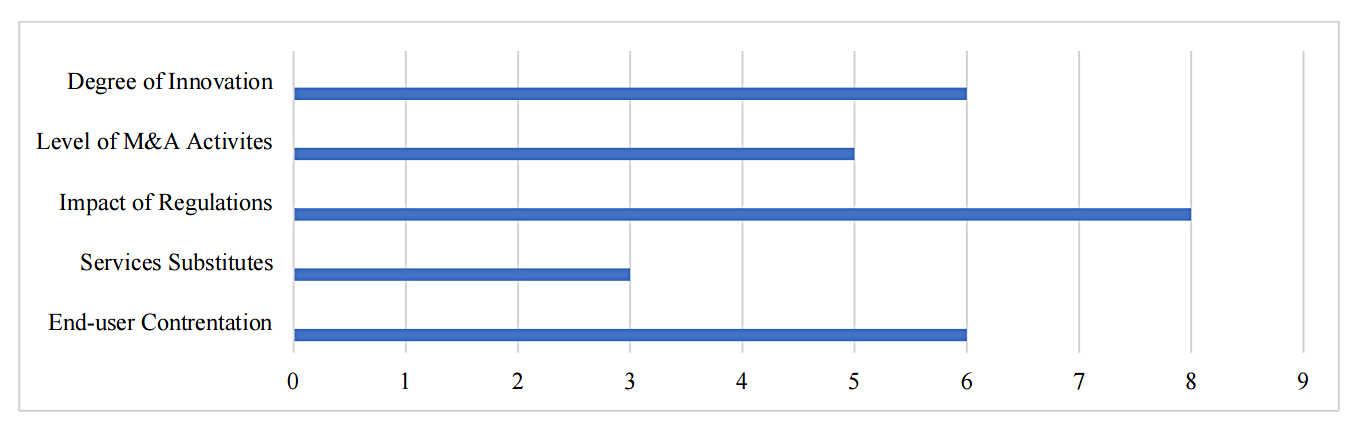

The “Intelligent Classroom” project is a digitization experiment, during which new technologies are used with virtual learning. The development and impact of interactive parts, augmented reality (AR) and virtual reality (VR), as well as AI and IoT (Internet of Things) are motivating. The concentration of the educational technology market and the prominence of its characteristics are illustrated in Figure 2, which shows the high level of innovation and the significant impact of technology on the change of education, as it can already serve individual needs. There is an increase in investment in the sector, and traditional classrooms are being transformed. The business share rate in the area is high, reaching 68.55% of global revenue. Concentration, partnerships between institutions and content developers represent new potential for digitization, industry competition in the field of educational technology market is becoming more intense [45] (Figure 2).

Figure 2. Educational Technology Market—Industry Competition. (Own editing, based on [45].)

Figure 2. Educational Technology Market—Industry Competition. (Own editing, based on [45].)

A problematic point, the data protection of the students participating in the training, is also guaranteed by law, due to EU regulations, EdTech is subject to the GDPR (General Data Protection Regulation). During the Smart Classroom project, advanced technologies based on virtual learning are used [45]. The use of AI in education raises several ethical and data protection issues, such as excessive collection of student data, algorithmic bias, and lack of transparency in automated decision-making. Although the EU GDPR regulation contains strict requirements, many EdTech systems do not fully comply with these principles. The ownership and management of data collected by AI is a particularly sensitive issue, which also affects student rights and equal opportunities in education [46,47].

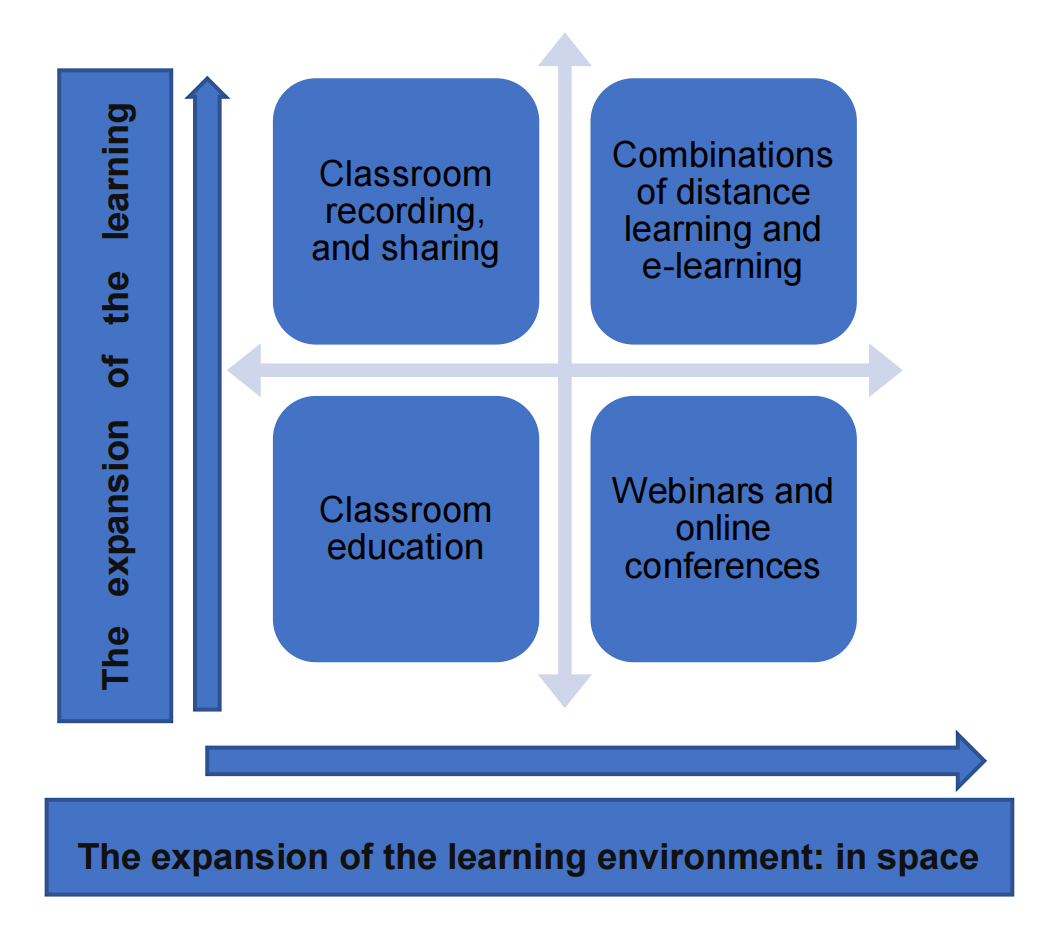

Open online courses (MOOC—Massive Open Online Course) that provide the opportunity for mass participation are mostly free and may require registration. These interactive forums appeared in the Anglo-Saxon areas in 2008 and spread from there in the field of distance education. The MOOC became really popular in 2012, and the reason for this is the quality of the material covered, the commitment of the instructors and the interaction between the participants in the training, but the issue of ethical use and free access is becoming an increasing problem [45,48,49] (Figure 3).

Figure 3. Traditional education—distance-learning position. (Compilation of authors, based on [45].)

Figure 3. Traditional education—distance-learning position. (Compilation of authors, based on [45].)

As a result of digitization, digital classrooms play an increasingly important role in the education segment. In 2022, 36.64% of the profits of the EdTech sector were controlled by North America and according to the forecasts, it will maintain its primacy, the new trend will be game-based learning [45]. EdTech investors came from China, the United States, Europe and the United Kingdom, and the amount of their investments already reached 20 billion dollars in 2021 [48,50]. Since the server is essential for digitization, the popularity of server locations will also affect the technical development of the given country. According to the popularity ranking based on server usage, in 2024, 1st is the United States with 33.8%, second Germany with 11.3%, and 3rd France with a value of 5.5%. Where the most popular content languages are tied?

Based on the February 2024 survey of the World Wide Web Technology Surveys, among the content languages, 1st English 51.2%, 2nd Spanish 5.6%, 3rd German 5.0%, 4th Japanese 4.6%, and 5th Russian with a usage value of 4.4%. The fastest growing content language since February 1, 2024 is German. As of June 1, 2024, French replaced Russian in the 5th place [40] (Table 1).

The intersection of education and AI has countless possibilities, including personalized education and catch-up, but the risk factors are currently unknown [51]. Visualization according to individual needs can be created with the help of the Education Databot AI-enhanced data visualization tool, which uses SDG 4 data in order to present educational data with a higher quality. The data visualization of OpenAI GPT-3.5 Turbo and Azure OpenAI API is also specially based on UNESCO statistical data, using the data of the fourth sustainability goal (quality education) during its operation [52].

According to international research, educational technology developments related to SDG 4 objectives have produced a number of measurable results. In countries where AI-based, personalized learning platforms have been introduced to develop basic skills, students’ reading comprehension and mathematics performance have improved by up to 12%–20% compared to traditional teaching methods [53]. Another positive result is that distance-learning programs supported by digital tools, for example in Nigeria, have increased access to education for disadvantaged students, thereby reducing learning inequalities [54]. These results show that well-designed EdTech interventions actually contribute to the global advancement of quality education. Although market research data (e.g., Grand View Research, W3Tech) predict rapid growth in the sector, they do not sufficiently address the issue of regulatory and pedagogical integration. There is little information available on how these technologies will actually be implemented in educational practice, or how their impact will be measured beyond financial indicators. Despite the goal of quality education, studies on educational innovation rarely address ESG frameworks, while sustainability-focused research does not address the technological and pedagogical aspects of AI-based education. This is a significant interdisciplinary gap and may support the need for integrated models. The importance of SDG4 is emphasized by many sources, but few studies discuss the long-term risks, such as the decline of the teacher role, the lack of transparency in data collection for educational purposes, or even the suppression of critical thinking. These undervalued aspects reinforce the need to evaluate technological developments according to normative, value-based criteria, not just economic performance.

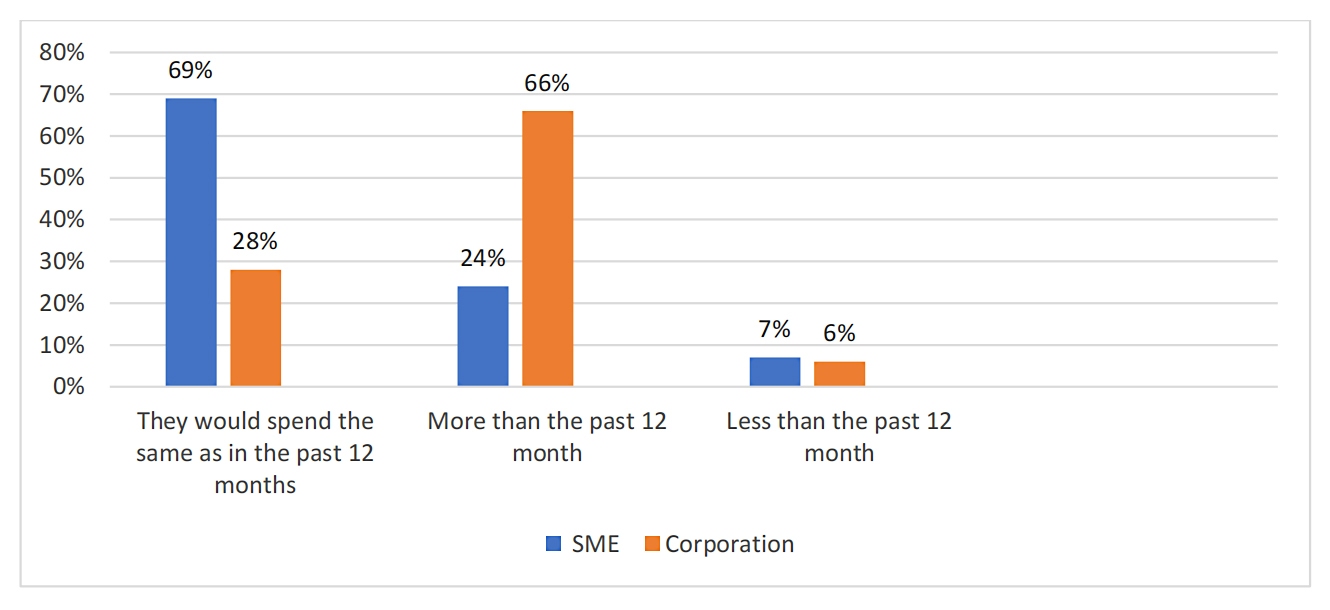

Labor Market-EmployeesWhat impact does AI-based educational technology have on the skill level of employees? How sustainability is reflected in educational technology ESG reports? The intertwining of education and the labor market is not new, the formulation of a common sustainability direction is essential. The sustainable financing package adopted by the European Commission in 2021 is ESG tries to capture non-financial risks and opportunities through reporting obligations [37]. The EU's Corporate Sustainability Reporting Directive, which entered into force in 2023, and the Sustainability Reporting Standards, which govern reporting requirements, require companies to regularly disclosing information on the environmental and social impacts of their activities, sustainability operations and performance [55]. According to a survey conducted by BDO Hungary's financial consulting group, companies in the region believe that ESG points of view cannot be avoided either, but compliance is still in its infancy, although 83% of the surveyed companies predict that it will have a major impact on their business results and reputation. 40% of the regionally surveyed companies would be happy to spend even more money to achieve ESG goals. 77% of large companies focus on energy and green energy investments, SMEs focus more on social areas and 15% more consider education and further training to be more important areas [23] (Figure 4).

Figure 4. How would companies change their ESG spending in the future? (Own editing, based on [23].)

Figure 4. How would companies change their ESG spending in the future? (Own editing, based on [23].)

AI tools suitable for sharing the latest knowledge have also become unavoidable from the point of view of the labor market. ChatGPT is already suitable for increasing global GDP. The rate of growth can reach up to 7%, since ChatGPT can simultaneously replace up to 300 million full-time workers. AI greatly threatens the jobs of employees in higher positions, while previous forecasts clearly predicted the mechanization of physical jobs. Automation can appear only as a supplement to the workforce, it can increase demand and generate jobs, and the increase of capital and workforce stimulates modernization. Technical scientific possibilities are not equivalent to technological reality, the quantified value of human work will be determined by the entry limits of the given role, which are generated by education and training [56]. The AI designed by Artisian AI is already able to integrate into the work of human teams, and in the future, the “Ava” development, which is an improved version of Chatbots, is suitable for replacing what people call boring jobs, including sales jobs [57].

Market competitiveness can only be improved by rapid adaptation to new trends. In a world dominated by AI, interpersonal skills, empathic and creative skills are becoming more and more important, making the given employee valuable. Christopher Pissarides [17] in connection with the research of science, technology, engineering and mathematics (STEM) subjects warns that the summarization, comparison and innovative application of data will make AI even more advanced, so that developers will soon become indispensable for the first time. With the development of AI, the need to fill areas that cannot be replaced by AI may increase, since creativity, managerial approach; empathy cannot be replaced with technical solutions [55,58].

In order to create a competent layer of employees in the workplace, a quick reaction is necessary, further training is replaced by retraining, which requires a much shorter time [59]. Retraining must be included in the company's strategy, since efficiency and productivity can be increased together with raising the qualification level of the workforce. During mentoring, Generation Z expects individual talent management and challenges during international projects, research, and professional internships [60]. The management of the process, which is also a compulsion for employees, can only be achieved through effective cooperation between the state apparatus, companies, businesses and the education sector [61].

According to experience, company managers most often ask employees about workplace development, training, and digitalization through surveys and questionnaires [62]. Based on the results of the surveys, the company's commitment to the development of its employees becomes measurable, possible shortcomings and areas to be developed in the adaptation of new technologies are also revealed. Staff training and development programs, their efficiency and participation rate in the field of new technologies can be monitored. Most of the information can be found on the companies' websites, in their annual reports, in reserved places. It is of informational value what kind of training, training or other development opportunities companies offer to their employees in the fields of innovation, and it is also worth considering the opinions and research of industry analysts and experts [63].

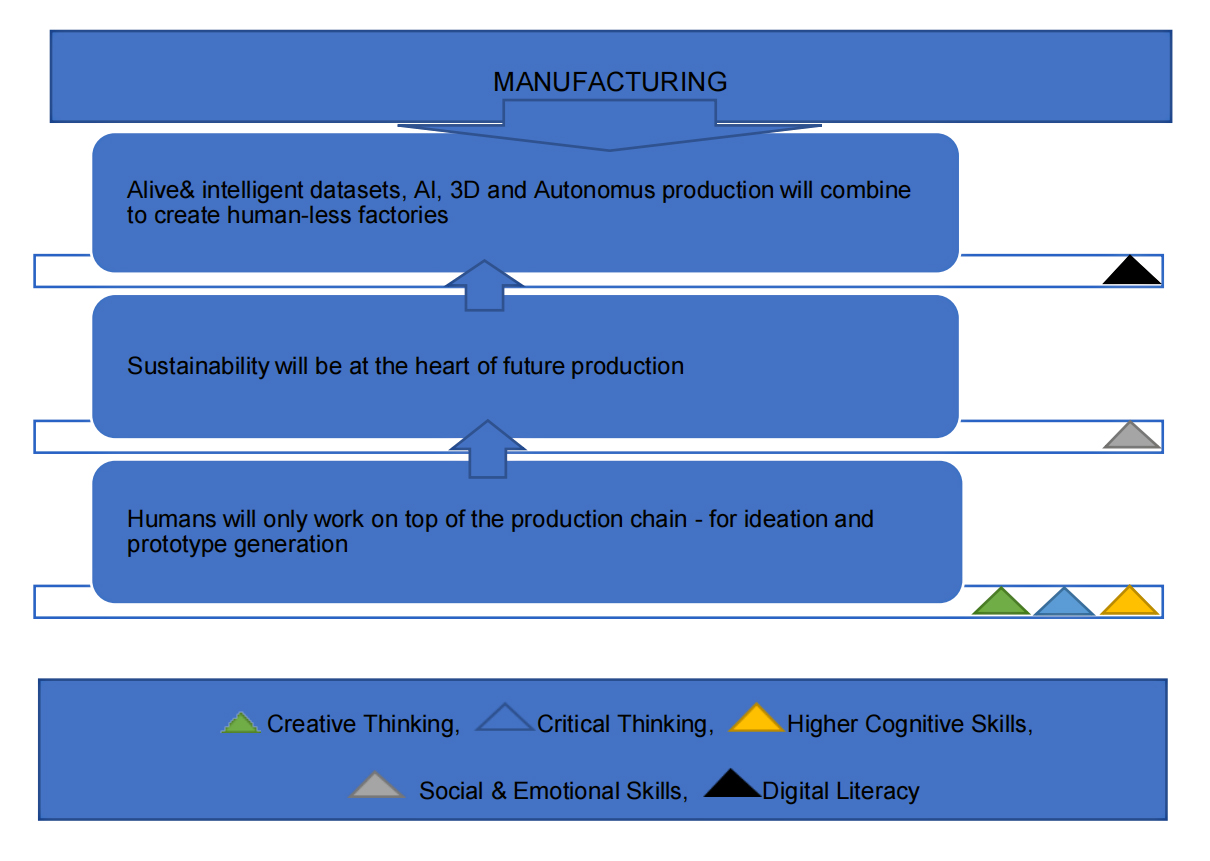

According to Randstad's market survey (Employer Brand Research), the most important employee expectations in 2024 are wages and other benefits, work-life balance, workplace stability, workplace atmosphere, fairness initiatives, fair development and career opportunities. Based on the data, the content of the work and the general perception of the company are more important in Europe than in Hungary [64]. The transformation of the labor market is indicated by the fact that, as a result of the application and advance of the fourth industrial revolution, AI, every fifth job will disappear in the future. This tendency must be responded to quickly due to the macroeconomic trends, the increase in the cost of living, the lack of supply, rising input costs and the process of slow economic growth. It can be a solution that the most dynamically growing function is performed by technology, digitalization and sustainability [65]. By 2025, almost 50% of jobs will be automated if the given conditions are created, and 65% of students still studying in the education system today will work in a new type of work [35] (Figure 5).

Figure 5. The future of work. (Compilation of authors, based on [35].)

Figure 5. The future of work. (Compilation of authors, based on [35].)

In the future, due to the important role of mastering new technologies and the skill defect of the workforce, a 10% increase in the education division can be forecasted in vocational education and in the university and higher education segment. Analytical and creative thinking, flexibility, motivation and self-awareness, curiosity and lifelong learning will become indispensable for the employees of the future. Adaptability, reliability, analyzing details, technical literacy, cooperation with others, empathy, leadership and quality control complete the top 10 list of expected basic skills, the level of the most important skills can be improved with education. Developing the workforce and attracting talent are definitely management tasks. The role of young workers in the economy would show enhanced value, but currently their potential lack of employment can be monitored. Negative values can still be detected in Eastern Europe, while a positive shift is already visible in Northern, Southern and Western Europe [65]. Compared to 2019, the employment deficit in Northern, Southern and Western Europe improved from −5.5% in 2020 to 1.0% in 2022, and in Eastern Europe, it changed from −7.2% to −5.3% in 2020. The above data are estimates until 2021 and forecasts for 2022. Young people represent the age group 15–24. The values show a favorable process, but the improvement is not yet at a sufficient level [66] (Table 2).

According to the latest forecasts, the earth's population is expected to peak at 9.73 billion people by 2064, by 2100 it will decrease to 8.79 billion people, and by 2050, a third of the 15–24-year-olds will be of African origin, who will enter the labor market as employees [67]. Productivity is declining worldwide, which the use of AI can improve. Due to the aging of the population, the peculiarity of young people, the fluid intelligence necessary for creative problem solving, is also decreasing, digitization can be the solution to replacing the workforce and increasing efficiency [68]. In the past, aging already played a 35% role in the use of robots, especially in the extremely aging societies of Germany, South Korea and Japan, because demographic changes entail faster technological change [69]. Currently, AI may emerge as a strategic solution to alleviate labor shortages and sustain economic growth. There are regional differences in the impact of AI on the labor market. In North America, AI has been rapidly adopted, dominated by technology companies, and the survival of intellectual jobs is at a higher risk, while in Europe, the pace of AI adoption is slower and is implemented in a regulated environment. In China and Asia, AI operates with strong state support and plays a major role in manufacturing and education, while in the Global South and developing regions, the introduction of AI has been mostly delayed, and we can only talk about digital remote work [70–72].

The adoption of technological development fundamentally affects workplaces. Based on the analyzes of the Future of Jobs Survey, by 2023–2027 Digital platforms and applications are likely to be used by 86.4%, Education and workforce development technologies 80.9%, Big-data analysis 80%, and Artificial intelligence 74.9%, based on feedback [65]. The technological transformation of the workplace is not a future possibility, but a rapidly approaching reality. For companies and workers, technological adaptation is becoming an inevitable competitive factor, redefining the way work is done, organizational structures, and the skills required.

The appearance of large language models (LLMs), is the next significant innovation change. Generative artificial intelligence (genAI), which will be important for businesses with new data generated based on previously created data, can increase productivity, but many people feel it is dangerous for society. According to Jensen Huang, the CEO of Nvidia, the development of artificial intelligence is reaching such a scale that within five years it will be able to pass tests that correspond to human thinking [73]. ChatGPT 4.5 may even surpass humans in the near future [74].

According to Nobel Prize-winning economist Christopher Pissarides, previously urbanization, then the entry of women into work, and now, on the threshold of the fourth industrial revolution, the emergence of a new resource (AI) are once again generating changes. First the power of steam, then electricity, the advent of computers and now automation, AI, which affects the transformation of the labor market. At the moment, robots cause an improvement in productivity, so the most sought-after employees will need IT skills, they must understand data processing, operations, logistics, and have engineering expertise. The reliable, creative employee who has sufficient self-discipline, but at the same time critical thinking, and thanks to his good communication skills can easily share his opinion with his colleagues and managers, continuous development and learning are valued, the love of new technology becomes indispensable [17,75]. Based on the interpretation of this forecast, education definitely forms the basis of economic growth due to higher productivity, innovation skills, and the diffusion of innovation, but a diploma is an increasingly less desirable condition. The attitude, ability to perform, potential inherent in the person, which is authoritative [76].

The application of AI in practice is no longer just a modernization tool, but a strategic tool for solving the most complicated problems [36].

Currently, however, AI is not yet suitable for the standards of industrial control systems (OT—operational technology), as it is not always accurate, which can be particularly risky for the industrial environment. Nokia’s MX Workmate, an industrial AI application developed for this problem, is able to perform an interpreter function, where, using the Generative AI Large Language Model technology, it will be able to translate technical language into common language and vice versa, colloquial expressions can also become suitable for control with its help, employees they will be able to control more complex systems even with lower professional knowledge. This factor can become one of the solutions to the labor shortage [16]. Although AI could potentially displace millions of jobs, it is more likely to play a primarily complementary role, as its introduction may be associated with high costs, social resistance, and ethical dilemmas. The issue of youth employment also requires significant regional studies based on the assumption of heterogeneous competence levels and employee diversity.

The primary aim of this study was to examine sustainable and responsible educational technology efforts and the cooperation of artificial intelligence for the sake of future workers. The study helps to introduce new thinking frameworks, even if it does not offer strong statistical analysis. The empirical foundation was strengthened through a comparison of ESG strategies among Hungarian, German and Nordic companies. According to the results of this research, digital transformation fundamentally transforms the labor market. This is supported by Audi Hungaria’s annual report [13], which identifies flexibility, openness to new knowledge, lifelong learning, and the ability to adapt quickly as the most valued employee attributes in the production sector. In the organizational system, development is stimulated by employees who train themselves from internal motivation and motivate their environment, the role of retraining and further training is enhanced compared to traditional educational frameworks. Several practical proposals aim to stimulate development: the introduction of modular, micro-accredited training systems (e.g., EU DigComp, IBM SkillsBuild); AI-assisted learning path planning (Skill Navigator); the integration of technological and cultural practices (Tech+Humanity Labs); learning through practical experience (e.g., AI coaching), joint innovation incubators bridging education and industry (dual-innovation labs); AI mentoring programs for young people and early-career professionals; and the implementation of digital portfolio-based assessment (e.g., project work, blogs). The transformation of the educational technology market is also fundamentally influenced by regulations. Recognizing the influencing factors in the transformation is the company’s responsibility by creating organizational charts, using organizational network analysis, interactive joint work, and corporate synergies. As practical implications we can conclude, that the key to competitiveness is the ability to innovate, improve the portfolio, control efficiency, community engagement, and continuous motivation. Diversity is a key element of sustainability, and successful transformation requires flexibility, lifelong learning, the practical application of knowledge, and effective recruitment strategies within organizational development.

It is in the self-interest of companies that wish to maintain their competitiveness to think about recruitment, primarily to develop with the help of dual training, even in the field of adult training and higher education, but important factors are the development of retraining, professional competences, soft skills, and shortened training programs. Universities are primarily looking for solutions and development results from a scientific point of view, while companies prioritize economic and industrial aspects. According to the research results, the theoretical process of digitization, AI, can make previous automated processes more efficient. From 2025, the report on ESG indicators will be verified by external auditors for compliance with CSRD. If the CSRD data is connected with the financial and production data, the formulation of correlations and directions in the primary stage will be successful. With the use of ESG data, it becomes necessary to localize the data points, connect the data, use AI, and then integrate the conclusions and measurement results into the planning processes.

The most important research result of the study is that the fourth goal of the SDG (Quality Education), is compared with the latest educational technology, labor market, and AI-related current issues and the answers are supported by the latest practical data. The study provides evidence, supported by statistical data that the educational technology market is growing dynamically, the labor market is undergoing significant transformation, training is becoming shorter and more digitalized, and soft skills are gaining value. However, these developments alone are not sufficient. The literature review reveals additional challenges, such as the impact of AI on the workforce, the role of ESG in education, data limitations, regulatory lags, gaps in provision, skill shortages driven by AI, the digital divide, the ongoing need for educational reform, and new directions for research.

The limitations of the research are that the results of the analyzes are specific to a narrow geographical area and only to specific organizations, and the data revealed for processing can accordingly only affect a small segment of the investigated areas. While the primary data reflect Central European trends, they can form the basis for broader comparative international studies.

The future research direction is to expand the geographical boundaries of the research and the number of studied organizations in order to establish the most well founded conclusions. If we compare the test results with the existing literature, the novelty and the theoretical implication of the research is that the role of digitization is supported by a new, unique justification, which includes further innovative thinking and development ideas. AI is becoming an integral part of everyday life, but its use must be underpinned by responsible and ethical conduct from both developers and society.

In the spirit of preparation for approaching full employment, effective competitiveness requires digitization developments, as well as the effective cooperation of innovative companies, educational institutions, and government agencies [60]. Developments designed to increase production volume are replaced by the management of labor shortages and the reduction of energy costs, the shift towards technological innovations, and the importance of retraining increases. Productivity within production can also provide a motivating force. Following the possession of system data suitable for the industrial use of AI, conclusions can be drawn and injected into the management process. Efforts concerning sustainable and responsible educational technology and labor market supply can become effective in cooperation with the use of artificial intelligence for the benefit of the workers of the future [11]. Future research should explore the long-term effects of AI on educational equity and corporate responsibility in different regions. In 2024, AI systems accounted for approximately 1%–1.3% of global electricity consumption, a figure projected to rise to 3% by 2030. This underscores the needs to explore energy efficiency and develop green AI strategies [77].

The study’s interdisciplinary approach to the future of education and he labor market transformation aims to address an existing research gap. Empirically, the critical comparison of secondary sources and the mapping of the literature all contribute to setting the direction of future research and point out the existing theoretical and practical shortcomings, according to which the full-scale introduction of AI has regional, industry, ethical, technological, and budgetary limitations, and the introduction of young people into the labor market may have varying results despite appropriate mentoring due to employee diversity and different levels of competence.

All data generated from the study are available in the manuscript.

Conceptualization and methodology, ZK, VGK and MKS writing—original draft preparation, ZK; writing—review and editing, VGK and MKS; visualization, ZK; supervision, VGK and MKS; All authors have read and agreed to the published version of the manuscript.

The authors declares that there is no conflict of interest.

1.

2.

3.

4.

5.

6.

7.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

25.

26.

27.

28.

29.

30.

31.

32.

33.

34.

35.

36.

37.

40.

41.

42.

43.

44.

45.

46.

47.

48.

49.

50.

51.

52.

53.

54.

55.

56.

57.

58.

59.

60.

61.

62.

63.

64.

65.

66.

67.

68.

69.

70.

71.

72.

73.

74.

75.

76.

77.

78.

79.

80.

82.

83.

Kaszalik Z, Gősi Kövecses V, Konczos Szombathelyi M. Overview on the sustainable and responsible educational technology efforts using artificial intelligence for the workers of the future. J Sustain Res. 2025;7(2):e250039. https://doi.org/10.20900/jsr20250039.

Copyright © Hapres Co., Ltd. Privacy Policy | Terms and Conditions